Table of Contents

Various types of conveyor systems are the backbone of efficient industrial operations, enhancing productivity and ensuring smooth material handling processes. In this blog post, we explore five critical types of conveyor systems, which play a pivotal role across various industries, from manufacturing to distribution. Understanding the characteristics and uses of each can help businesses like Lafayette Engineering optimize their operations for maximum efficiency.

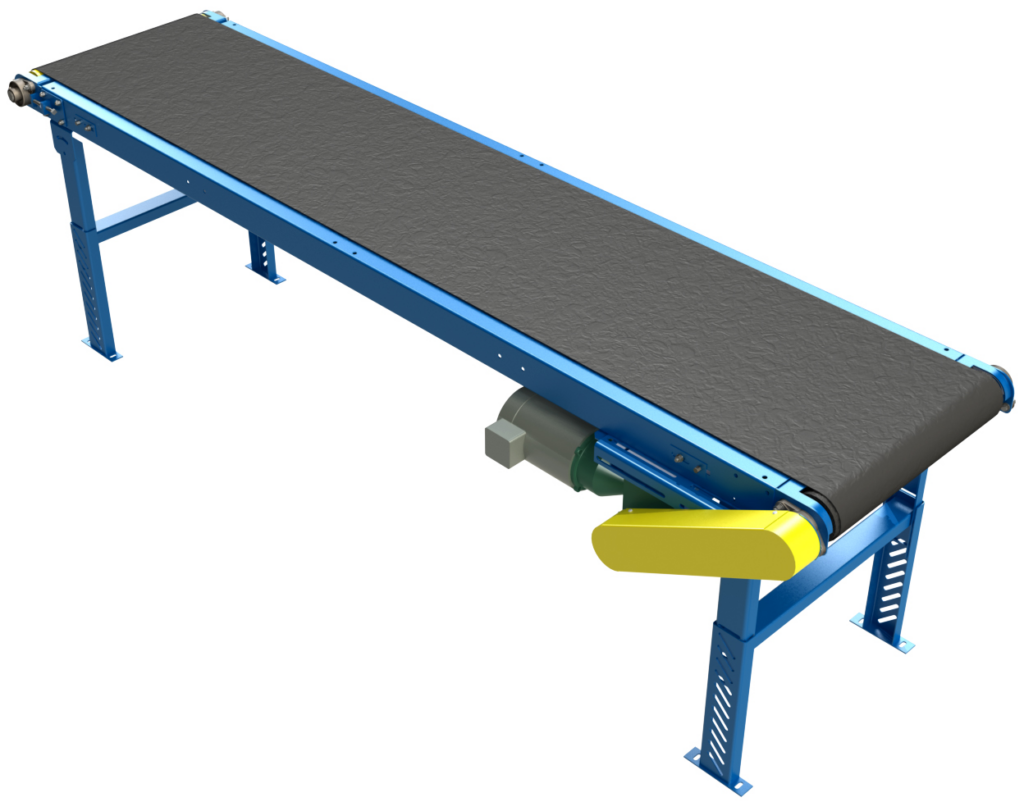

1. Belt Conveyors

Belt conveyors are among the most common types of conveyor systems. They consist of continuous belts that operate over rollers and are used to move materials over a fixed path. These systems are highly versatile and can transport a variety of materials, including bulk items and discrete products. They are particularly beneficial in industries like mining, automotive, and logistics, where they handle tasks ranging from ore transportation to assembly line operations and baggage handling.

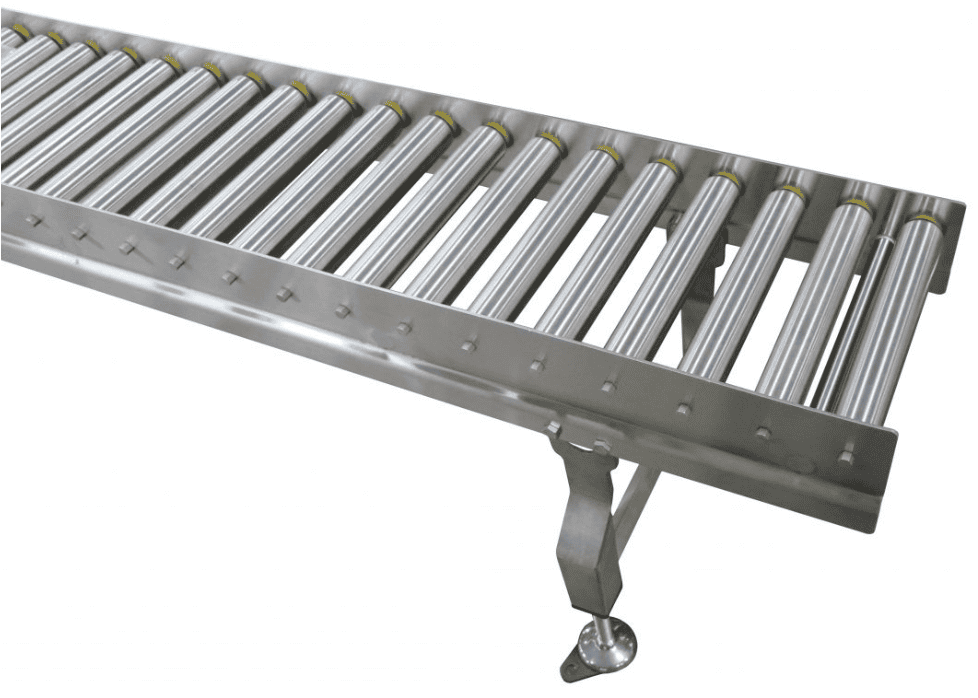

2. Roller Conveyors

Roller conveyors utilize a series of rollers to move goods either by gravity or manual pushing. These conveyors are ideal for handling stable, flat-bottomed items and are widely used in shipping and packaging facilities, as well as in baggage and mail sorting centers. The simplicity of their design contributes to their popularity in material handling, allowing for easy installation and maintenance.

3. Powered Roller Conveyors

This type of conveyor adds an electrical element to the traditional roller system, enabling the automatic and controlled movement of goods. Powered roller conveyors are suitable for heavier loads or where controlled movement is necessary, such as in food processing, steelmaking, and packaging applications. Their ability to regulate the speed and handling of products makes them invaluable for precision tasks.

4. Overhead Conveyors

Overhead conveyors maximize floor space by utilizing the ceiling area for material transport. These systems are commonly used in industries such as automotive and painting, where parts need to be handled carefully and often require processing from multiple angles. The versatility of overhead conveyors allows them to be set up in complex paths, making them ideal for facilities with limited floor space.

5. Magnetic Conveyors

Magnetic conveyors are specialized for moving ferrous materials and are often used in machining and scrap handling. They utilize magnetic fields to propel metallic materials along the conveyor path without direct contact, which helps in reducing wear and tear as well as contamination. These conveyors are particularly useful in settings where chips and other metal debris need to be cleared away from production machinery efficiently.

Types of Conveyor Systems by Lafayette Engineering

Determining the right type of conveyor system for your material handling needs is crucial to achieving operational efficiency and cost-effectiveness. Lafayette Engineering excels in providing bespoke conveyor solutions that fit precisely with your unique industrial requirements. Here’s how Lafayette can guide you in selecting the perfect conveyor system for your operations:

Expert Consultation and Assessment

At Lafayette Engineering, the process begins with a thorough consultation to understand your specific material handling requirements. This includes evaluating the types of materials to be conveyed, the necessary speed, load capacity, and the environmental conditions of the operation area. Whether you need to transport heavy machinery parts in a manufacturing setting or delicate items in a distribution center, Lafayette’s team of experts uses their deep industry knowledge to recommend the most suitable conveyor types.

Custom Design and Integration

Once your needs are clearly defined, Lafayette’s engineers tailor a conveyor system design that integrates seamlessly with your existing processes. Utilizing cutting-edge technology and innovative design principles, they ensure that the conveyor system enhances workflow efficiency without disrupting your operations. This might include customizing the conveyor layout to fit into limited spaces or designing a system that can handle varying load sizes and weights.

Implementation and Optimization

With a design in place, Lafayette oversees the meticulous installation and commissioning of the conveyor system. But their involvement doesn’t end there; they also provide ongoing support and optimization services to ensure that the system continues to operate at peak efficiency. Lafayette’s approach includes regular maintenance checks and upgrades that adapt to evolving operational needs or technological advancements.

Training and Support

Understanding that a conveyor system is only as good as the people operating it, Lafayette provides comprehensive training for your staff. This ensures that your team can fully leverage the conveyor system’s capabilities, leading to reduced downtime and increased productivity.

By partnering with Lafayette Engineering, you’re not just installing a conveyor system; you’re enhancing your entire material handling strategy. Their holistic approach guarantees that the selected conveyor system will deliver optimal performance and support your business’s growth and efficiency goals.

Conclusion

The strategic implementation of these conveyor types can lead to significant improvements in productivity and operational efficiency. Each type offers unique advantages and is suited to specific tasks and environments. Lafayette Engineering, with its focus on innovative material handling solutions, can leverage these technologies to enhance their service offerings and meet the diverse needs of their clients.

For more detailed information on conveyor systems and their applications, visiting websites such as Ultimation Industries and The Enterprise World can provide valuable insights and guidance on selecting the right conveyor type for specific industrial applications.