LaFayette Engineering: Your Premier Partner in Control Systems Integration

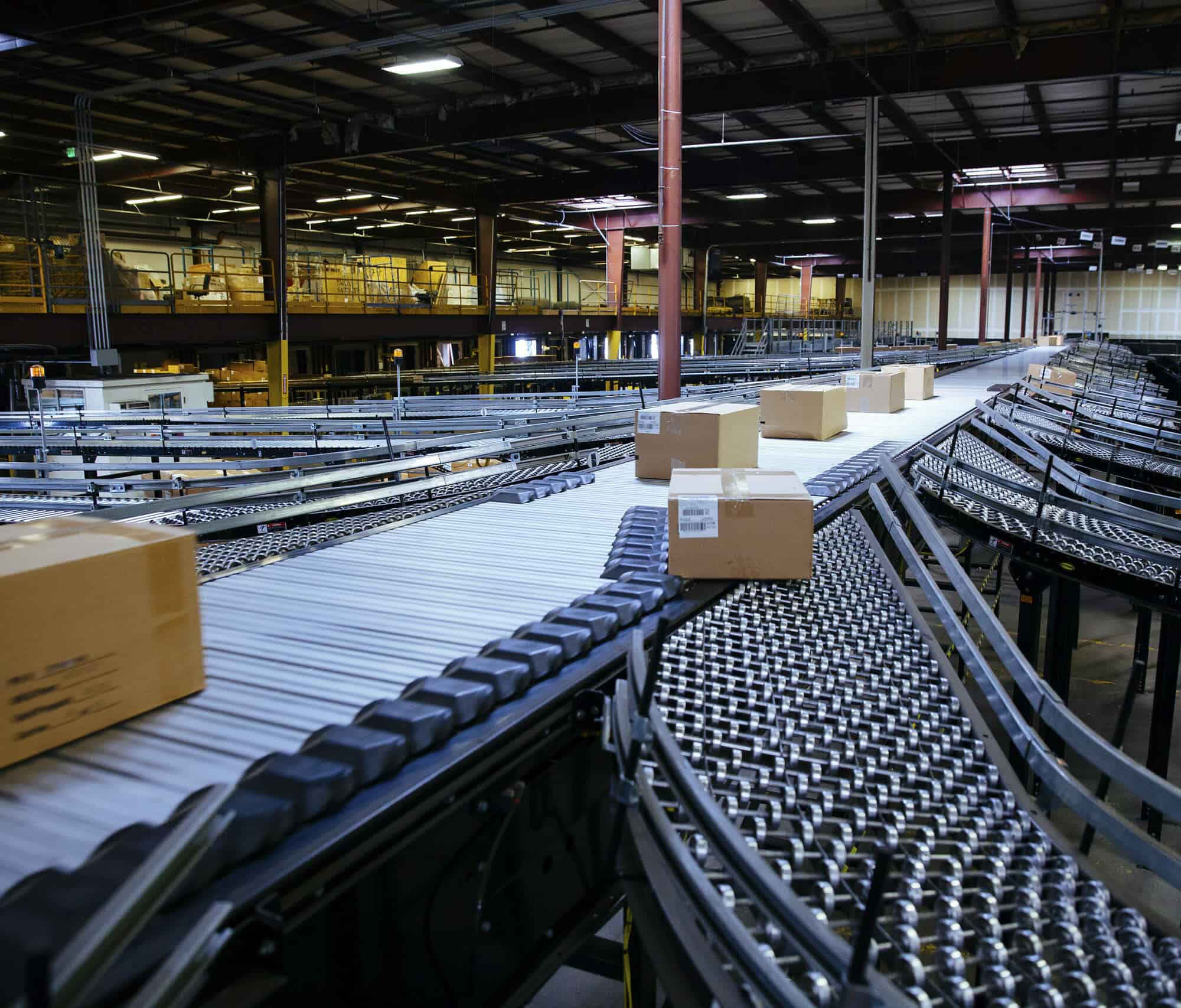

LaFayette Engineering, rooted in Danville, Kentucky, stands as a leading integrator of control systems, focusing on the design and execution of sophisticated conveyor systems for material handling. Our portfolio showcases successful collaborations with prominent companies, reflecting our prowess in tailoring conveyor solutions to both new and pre-existing warehouse and distribution facilities.

The cornerstone of any efficient conveyor system is its controls. At LaFayette Engineering, we meld our profound electrical engineering expertise with cutting-edge technology and control mechanisms. This fusion is aimed at amplifying equipment effectiveness, escalating system efficiency, curtailing operational expenses, and boosting productivity, all while ensuring adaptability in your material handling systems.

Crafting Bespoke Solutions for Material Handling

LaFayette Engineering dedicates itself to inventing, designing, and constructing customized solutions addressing typical challenges in material handling. Our team of seasoned engineers invests time in comprehending your distinct processes, collaborating closely with you to craft solutions perfectly aligned with your business requirements.

Our industrial automation systems are engineered prioritizing performance, precision, resilience, and dependability. These solutions are renowned for their industry-leading throughput and speed capabilities, rigorously tested before deployment in your facility.

In our control systems, we consistently employ open, non-proprietary components and programming structures. By utilizing components from established industry leaders for starters, relays, lights, switches, etc., we not only adhere to stringent quality standards but also guarantee the availability of spare parts locally and as required.

Whether it’s a new installation or an upgrade to an existing system, LaFayette Engineering can swiftly deliver a competitive quote for any control application. Our spectrum ranges from small-scale control panel projects to comprehensive, customized solutions for complex challenges, ensuring optimal value for your investment.

Our Methodical Approach to Project Execution

LaFayette Engineering’s meticulous process encompasses:

- Comprehensive assessment of your specific needs.

- Development of innovative conveyor concepts.

- Generation of detailed AutoCAD electrical control drawings, including panel layouts with bill of materials, motor power wiring, electrical schematics, input/output schematics, and field wiring diagrams.

- Fabrication of state-of-the-art control panels.

- Advanced PLC Programming with sortation logic.

- Thorough project management, from inception to completion.

- Coordinated installation processes.

- Field installation with precision.

- Development and tracking of punch lists.

- Launch assistance, providing start-up support directly at your facility.

- Continuous service and support, ensuring enduring system performance.

By choosing LaFayette Engineering, you partner with a team committed to driving your operational success to new heights through innovative and reliable control system solutions.