Table of Contents

The Emergence of Print and Apply Label Systems

In today’s fast-paced industrial landscape, efficiency and accuracy are paramount. This is where Print and Apply Label Systems come into play, revolutionizing the way businesses handle product labeling. These systems combine the processes of printing and applying labels into one seamless operation, significantly saving floor space and improving control over variable data on each product.

Introduction to Lafayette Engineering

Lafayette Engineering, a dynamic player in the industrial automation sector, has been at the forefront of providing innovative solutions to streamline production processes. With a focus on conveyor systems and controls, their expertise lies in enhancing operational efficiency and productivity for various industries. Their commitment to delivering high-quality, customized solutions makes them an ideal subject for discussing the integration and benefits of Print and Apply Label Systems in modern manufacturing and distribution environments.

Understanding Print and Apply Label Systems

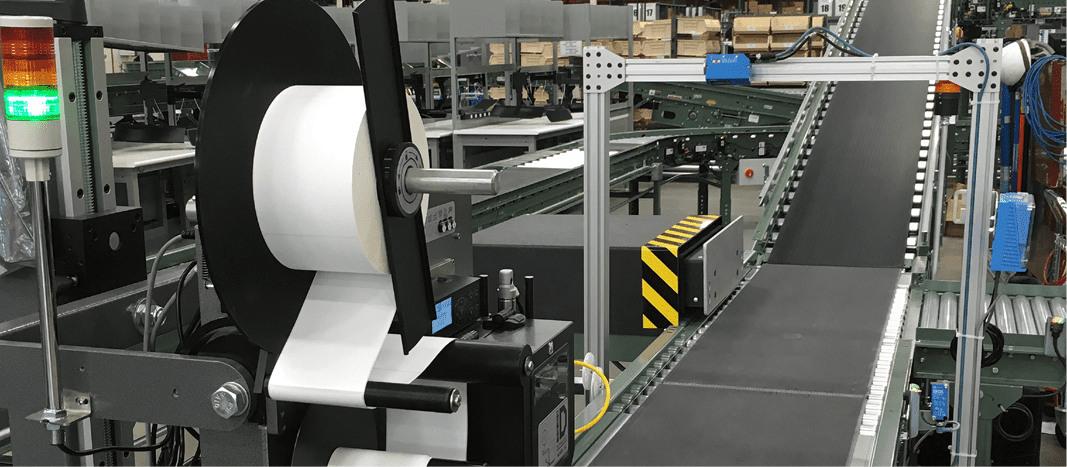

A Print and Apply Labeling System is an amalgamation of a label printer and a label applicator. This system is particularly beneficial for products or cartons requiring specific information like lot numbers, expiration dates, and shipping addresses. The key components of these systems include:

- Print Engine: A robust, high-speed printing module designed for industrial use, capable of enduring harsh production environments.

- Label Applicator: This component accurately places labels on containers.

- Programmable Logic Controller (PLC): It controls both the printer and applicator, interfacing with the operating technology system to manage label formatting and data generation.

Print Engines: Brands and Methods

Print engines in these systems are not your average office printers. They are designed for continuous operation in challenging environments. Brands like Zebra and Sato offer engines with varying specifications to suit different label sizes and print quality requirements. The printing technologies used are primarily:

- Direct Thermal Printing: Ideal for short-term applications like shipping labels, using heat-sensitive paper.

- Thermal Transfer Printing: Suitable for long-term legibility requirements, this method uses a heated print head to melt ink from a ribbon onto the label.

Label Application Techniques

The label applicator typically employs a tamp/blow method, where the label is held by a vacuum on a tamp and then applied to the container using a blast of air. This method adapts well to varying product loading speeds. Other methods like merge or air blow are also used depending on specific requirements.

Addressing Industrial Needs

Print and Apply Label Systems are designed to address two primary industrial challenges:

- Balancing Printing Speed with Product Loading Variations: A loose loop system creates a buffer for labels, allowing for consistent application despite varying product speeds.

- Flexibility in Label Usage: A web bypass feature enables the use of pre-printed labels without passing them through the print engine, maintaining high throughput.

Connectivity and Control

Modern Print and Apply Systems offer diverse connectivity options, including serial, parallel, Ethernet, USB, and wireless communications. This versatility ensures seamless integration into existing production lines, allowing for efficient control and data transmission.

Conclusion: The Role of Lafayette Engineering

Incorporating Print and Apply Label Systems aligns perfectly with Lafayette Engineering’s ethos of enhancing efficiency and productivity in industrial settings. Their expertise in conveyor systems and controls can be leveraged to integrate these labeling systems into existing production lines, offering clients a streamlined, efficient, and error-free labeling process. As industries evolve, the collaboration between innovative solutions like Print and Apply Label Systems and industry leaders like Lafayette Engineering will continue to drive the future of manufacturing efficiency.