Table of Contents

Conveyor system design is the backbone of efficient material handling in industries ranging from manufacturing to distribution centers. A well-thought-out conveyor system design not only improves productivity but also ensures safety and reliability, ultimately driving the success of your operations. In this guide, we’ll explore the key steps in the conveyor system design process, providing valuable insights and best practices to help you optimize your system.

At Lafayette Engineering, we specialize in creating custom conveyor systems tailored to meet the unique needs of our clients. Our team of experts is committed to delivering innovative solutions that enhance your operational efficiency. If you’re looking to improve or install a new conveyor system, we’re here to help. Connect with us on LinkedIn to learn more about our services and stay updated with the latest industry trends.

Understanding the Conveyor System Design Process

The conveyor system design process involves several critical stages, each requiring careful consideration and planning. Below, we break down these steps to give you a comprehensive understanding of how to create a successful conveyor system.

1. Define Your Objectives

The first step in conveyor system design is to clearly define your objectives. What are the specific needs of your operation? What materials will be handled, and what are the weight and size specifications? Understanding these factors is crucial in determining the type of conveyor system that will best suit your needs. Whether it’s improving speed, increasing capacity, or enhancing safety, your objectives will guide the entire design process.

2. Analyze the Operational Environment

Every conveyor system operates within a specific environment, and understanding this environment is essential for effective design. Factors such as temperature, humidity, dust levels, and potential exposure to chemicals must be considered. For example, a conveyor system in a food processing plant will have different requirements compared to one in a mining operation. By analyzing the operational environment, you can select materials and components that will withstand the conditions and ensure longevity.

3. Choose the Right Conveyor Type

There are various types of conveyor systems, each with its own advantages and applications. The choice of conveyor type is influenced by the material being handled, the layout of your facility, and your specific operational goals. Some common types include:

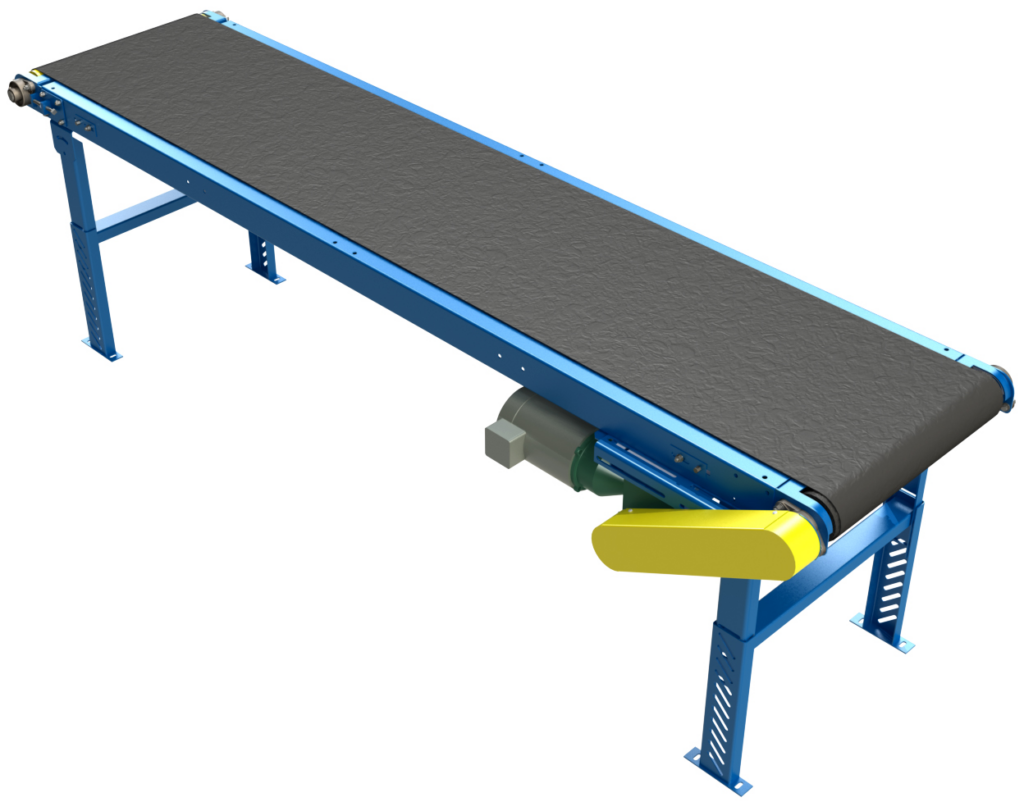

- Belt Conveyors: Ideal for moving materials over long distances.

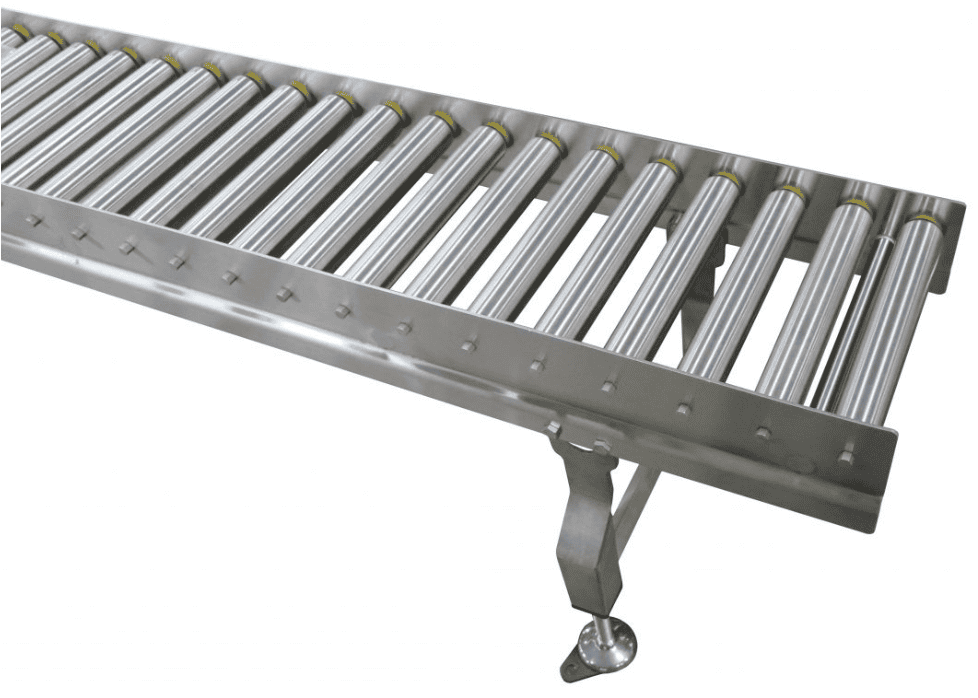

- Roller Conveyors: Suitable for handling heavier loads.

- Chain Conveyors: Best for harsh environments and heavy-duty applications.

- Slat Conveyors: Used for moving large, bulky items.

Selecting the right conveyor type is a crucial step in the conveyor system design process. At Lafayette Engineering, we offer a wide range of conveyor systems, and our experts can help you determine the best option for your needs.

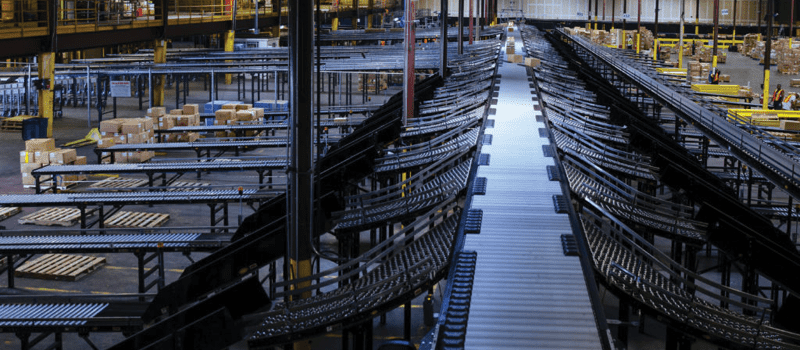

4. Design the Layout

The layout of your conveyor system plays a significant role in its efficiency and effectiveness. A well-designed layout minimizes material handling time, reduces bottlenecks, and optimizes space utilization. Consider factors such as the flow of materials, ease of access for maintenance, and the integration of other equipment. By creating a detailed layout, you can ensure that your conveyor system will operate smoothly and efficiently.

5. Consider Safety and Ergonomics

Safety should always be a top priority in conveyor system design. Implementing safety features such as emergency stop buttons, guards, and warning signals can prevent accidents and protect workers. Additionally, ergonomic considerations, such as adjustable heights and easy access to controls, can reduce the risk of injury and improve operator comfort. At Lafayette Engineering, we design conveyor systems with safety and ergonomics in mind, ensuring that your operations are both safe and productive.

6. Select the Right Components

The components of your conveyor system, including motors, belts, rollers, and controls, must be carefully selected to match the demands of your operation. High-quality components not only ensure reliable performance but also reduce maintenance costs and downtime. When selecting components, consider factors such as load capacity, speed requirements, and energy efficiency. Lafayette Engineering partners with leading manufacturers to provide you with the best components for your conveyor system.

7. Test and Optimize

Once your conveyor system design is complete, it’s essential to test the system before full-scale implementation. This testing phase allows you to identify any potential issues and make necessary adjustments. During testing, evaluate the system’s performance, safety features, and integration with other equipment. Optimization may involve tweaking the layout, adjusting settings, or upgrading components to ensure the system operates at peak efficiency.

8. Implement and Maintain

After testing and optimization, it’s time to implement your conveyor system. Proper installation is critical to ensuring that the system functions as intended. Following installation, regular maintenance is essential to keep your conveyor system running smoothly. Preventative maintenance, such as inspecting belts, lubricating moving parts, and checking controls, can extend the life of your system and prevent costly breakdowns. At Lafayette Engineering, we offer comprehensive installation and maintenance services to support the long-term success of your conveyor system.

Frequently Asked Questions (FAQ)

1. What factors should I consider when choosing a conveyor system?

When selecting a conveyor system, consider factors such as the type of material being handled, the operational environment, load capacity, speed requirements, and the layout of your facility. Additionally, safety and maintenance needs should be taken into account.

2. How do I ensure my conveyor system is energy-efficient?

To improve energy efficiency, choose energy-efficient motors, optimize the system layout to reduce unnecessary movement, and implement variable speed drives that adjust the system’s operation based on load requirements. Regular maintenance also helps to ensure that components are operating efficiently.

3. What are the benefits of working with Lafayette Engineering for conveyor system design?

At Lafayette Engineering, we offer personalized solutions tailored to your specific needs. Our team of experts has extensive experience in designing and implementing conveyor systems that enhance operational efficiency, safety, and reliability. We also provide ongoing support and maintenance services to ensure your system continues to perform at its best. Learn more about our services and connect with us on LinkedIn.

4. How often should I perform maintenance on my conveyor system?

Regular maintenance is crucial to the longevity and performance of your conveyor system. Depending on the usage and operational environment, maintenance should be performed at least monthly. However, high-demand systems may require more frequent checks.

5. Can Lafayette Engineering help with upgrading an existing conveyor system?

Yes, we specialize in both designing new systems and upgrading existing ones. Our team can assess your current system and recommend improvements to enhance performance, efficiency, and safety. Whether you need a minor upgrade or a complete retrofit, we’re here to help.

Conveyor System Design for Your Business

Conveyor system design is a complex process that requires careful planning and consideration. By following the steps outlined in this guide, you can create a system that meets your operational needs and delivers long-term value. At Lafayette Engineering, we’re committed to providing top-quality conveyor systems that drive success for our clients. Whether you’re designing a new system or upgrading an existing one, we’re ready to assist you. Connect with us on LinkedIn to stay connected and learn more about our expertise in conveyor system design.