Print & Apply

Solutions

Overview

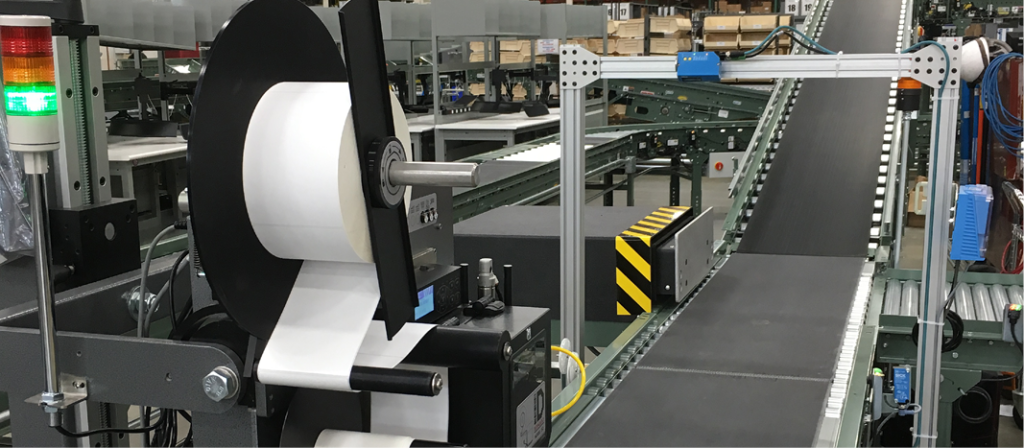

Print & Apply systems are created for automated processes in production lines. A standard Print & Apply system includes a barcode scanner to identify the packaged product, a print & apply machine to create the bar-code label, conveyor for inducting, labeling and rerouting of the product, a verification scanner to read the printed label, software to merge data and communicate with the host system.

- Retail

- Ecommerce

- Distribution

- 3PL

Benefits

Print & Apply systems allow distribution centers to send out products faster by minimizing operator handling and processing times within their facilities. Eliminating or minimizing operator ‘touches’ can improve a company’s throughput. Print & Apply systems also benefit companies who have products that are time stamped, serialized, or require a variation in every label by processing those specifications through the label machine.

- One-stop print and apply line equipped with controls, electrical wiring, scanner, and printer.

- Plug and play ready to tie into an existing system or ready to stand alone.

- ConveyorWorks WCS that can tie into any WMS.

- 40 Cartons Per Minute (CPM) Max with two printers.

- 20 CPM max with one printer

- Hytrol Conveyor with optional dimensions and other conveyor accessories

- Increases throughput rates and label verification

- Real-time statistics with a log of cartons ran through the system

- Real-time error log and diagnostic system summaries including line activity, history, exceptions, summary stats, detailed stats, printer status, and settings.

- Verification Scan stats for Print and apply.

- Label Verification stats for print and apply.

- In-line scale & dimensions