Table of Contents

Frequently Asked Questions (FAQ) about Human-Machine Interfaces (HMI)

1. What is a Human-Machine Interfaces (HMI)?

An HMI, or Human-Machine Interfaces, is a user interface that connects an operator to a machine, system, or device. It allows operators to control machinery, monitor processes, and receive real-time data, facilitating effective interaction between humans and machines.

2. Why are HMIs important in industrial automation?

HMIs are crucial in industrial automation as they provide operators with comprehensive control and visibility over complex systems. They enhance operational efficiency, improve safety, and aid in decision-making processes by offering detailed error notifications, system status overviews, and remote access capabilities.

3. How have HMIs evolved over time?

Initially, human-machine interactions were limited to physical controls and indirect monitoring. With digital advancements, HMIs have transformed into sophisticated interfaces, incorporating features like 3D representations of industrial environments, which offer more intuitive and accurate system overviews.

4. What are the benefits of using 3D models in HMIs?

Integrating 3D models into HMIs provides a more intuitive understanding of complex industrial environments. It enhances navigation, aids in troubleshooting, and allows for better identification of different facility areas, thereby increasing productivity and operational efficiency.

5. Can HMIs be customized for specific operational needs?

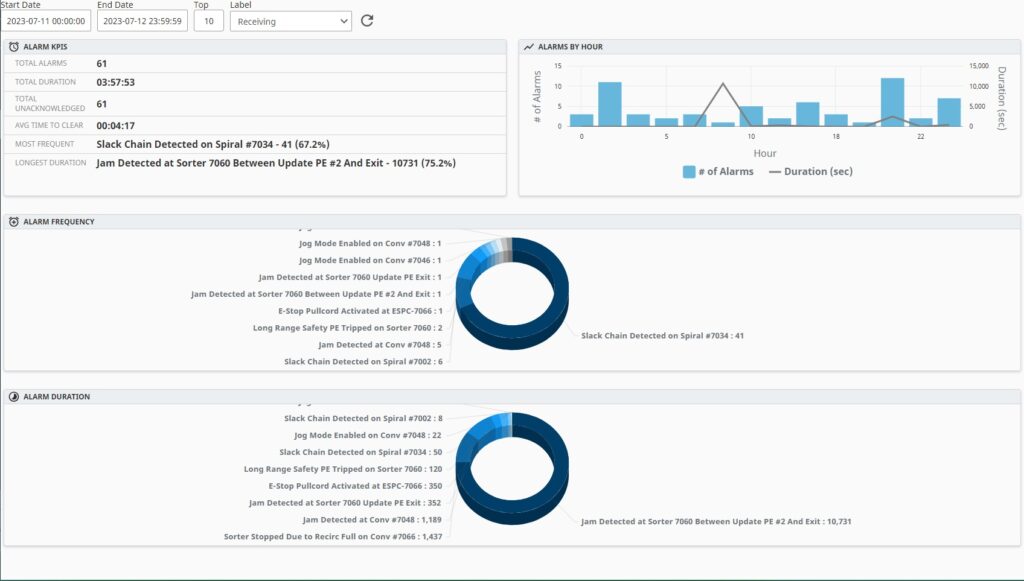

Yes, HMIs can be tailored to meet specific operational requirements. Customization can include labeling screens for individual facilities, incorporating to-scale 3D images, displaying live system statuses, and providing alarm logs and statistics pages to enhance accuracy in problem identification and resolution.

6. How do HMIs contribute to engineering efficiency?

By facilitating a deeper connection between humans and machines, HMIs optimize system performance and enhance safety protocols. They enable operators to make informed decisions promptly, thereby redefining the efficiency and effectiveness of engineering operations.

7. What is the future of HMIs in industrial automation?

The future of HMIs is set to become even more significant with continuous technological advancements, including the integration of artificial intelligence and machine learning. These developments will make HMIs more intuitive, predictive, and user-friendly, further transforming industrial operations.

8. What industries benefit most from HMIs?

HMIs are widely used across various industries, including manufacturing, logistics, energy, healthcare, and automotive. They are particularly valuable in sectors requiring precise process control, real-time data monitoring, and seamless human interaction with machinery.

9. How do HMIs enhance workplace safety?

HMIs play a crucial role in workplace safety by providing real-time alerts, system health monitoring, and error detection. Operators can quickly address potential issues, preventing accidents and minimizing downtime.

10. Are HMIs compatible with modern automation systems?

Yes, HMIs are designed to integrate seamlessly with modern automation systems. They support a variety of communication protocols and can interact with programmable logic controllers (PLCs) and other industrial equipment, ensuring smooth operations in advanced industrial environments.

For more detailed information on HMIs, refer to Lafayette Engineering’s comprehensive guide

About Lafayette Engineering, Inc. (LEI)

Lafayette Engineering, Inc. (LEI) is a leader in providing innovative material handling and automation solutions across various industries. Specializing in custom conveyor system design, retrofitting, and implementation, LEI leverages advanced technology, including Human-Machine Interfaces (HMIs), to optimize operational efficiency and ensure seamless integration of systems. With a commitment to quality and customer satisfaction, LEI works closely with clients to deliver tailored solutions that address their unique needs. Learn more about how Lafayette Engineering can help transform your facility at lafayette-engineering.com.