Table of Contents

Cross-docking has emerged as an innovative solution to streamline logistics and enhance supply chain efficiency, particularly for businesses managing warehouses. But with any logistics strategy, a central question arises: “Do I need cross-docking for my warehouse?” In this guide, we will explore what cross-docking is, the benefits and challenges it presents, and how to determine whether it’s the right fit for your operation.

What is Cross-Docking?

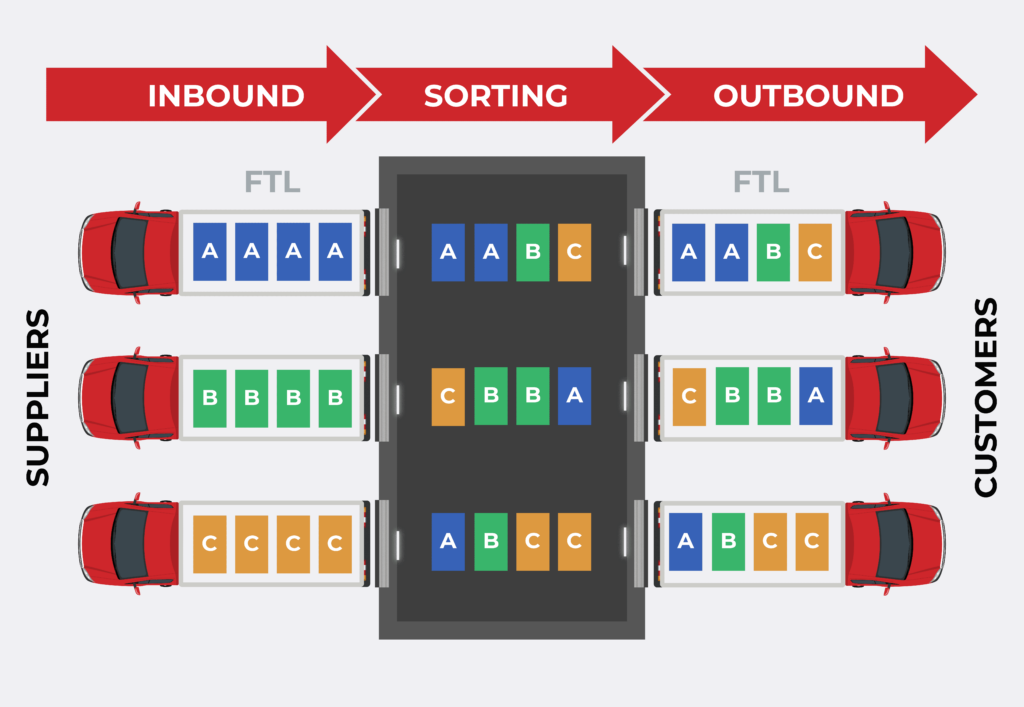

Cross-docking is a supply chain process where goods are unloaded from inbound trucks or railcars directly onto outbound vehicles with little to no storage in between. Unlike traditional warehousing, where products are stored for extended periods, it aims to minimize handling and storage time, leading to faster delivery.

Essentially, goods arrive at a distribution center or warehouse, are sorted based on their end destinations, and immediately transferred to outbound trucks, cutting out the need for inventory storage. It’s an appealing option for businesses looking to reduce warehousing costs and increase delivery speeds.

The Types of Cross-Docking

Before diving into whether its suitable for your warehouse, it’s essential to understand the various types of cross-docking processes:

- Manufacturing: This involves receiving inbound raw materials and parts, which are then grouped and sent directly to the manufacturing site. This method minimizes storage costs for materials and accelerates the production cycle.

- Distributor: Here, inbound goods are consolidated from multiple suppliers and then sorted and grouped for delivery to multiple customers. It’s common in retail, where various products from different suppliers are delivered to stores in one shipment.

- Retail: Retailers may use this type to quickly distribute goods to stores, reducing the need for warehousing and enabling rapid response to customer demand.

- Transportation: Large shipments are broken down into smaller ones, making it easier to deliver goods across a broader geographical area.

- Opportunistic: Used when goods are received and immediately required by a customer or production facility, skipping storage entirely.

Benefits of Cross-Docking

Cross-docking offers a wide array of benefits, but these advantages will only apply depending on the nature of your operations. If implemented correctly, here’s what your warehouse could gain:

- Reduced Warehousing Costs: By reducing the need for storage space, it minimizes warehousing overheads like inventory management, security, and utilities. Your business can focus on what it does best, rather than managing inventory.

- Faster Delivery Times: Eliminates the storage phase, speeding up the time it takes for goods to get from supplier to customer. Faster delivery leads to better customer satisfaction and potentially increased sales.

- Improved Inventory Management: With fewer goods stored for long periods, there’s less risk of inventory obsolescence, damage, or shrinkage. Businesses that deal with perishable or time-sensitive goods benefit greatly from this.

- Lower Transportation Costs: Allows for more efficient use of transportation resources. By consolidating shipments, businesses can reduce the number of trips required, leading to lower fuel costs and less environmental impact.

- Streamlined Supply Chain: Simplifies the supply chain by reducing steps in the process, minimizing errors and complications. This can lead to a more responsive, flexible supply chain.

Challenges

Despite its numerous benefits, cross-docking is not without challenges. Businesses need to weigh the pros and cons before making the leap.

- High Initial Investment: Implementing can require significant upfront investment in new infrastructure, technology, and staff training. For small or medium-sized businesses, this initial cost might be a barrier.

- Complex Coordination: Requires precise coordination between suppliers, warehouse staff, and transportation providers. If one link in the chain fails, it could result in delays and increased costs.

- Limited Suitability: Not all products are suited. Perishable goods, high-demand items, or products that require minimal handling are ideal candidates, but other items may require longer-term storage. Businesses with a diverse product mix might struggle to fully adopt.

- Reliance on Technology: Relies heavily on advanced inventory management systems and real-time data to ensure smooth operations. For warehouses without robust technological infrastructure, the transition can be difficult.

Do You Need Cross-Docking for Your Warehouse?

Deciding whether cross-docking is right for your warehouse depends on several key factors. Answer the following questions to determine if this aligns with your needs:

- Do you deal with perishable or time-sensitive goods? If your business manages items with a short shelf life or requires fast delivery times, could be highly beneficial. It ensures rapid movement from supplier to customer without wasting time in storage.

- Are you facing high warehousing costs? If a significant portion of your operating budget is going toward warehousing, cross-docking can reduce these expenses by cutting the need for long-term storage.

- Do you have reliable suppliers and transportation partners? Requires efficient coordination between suppliers, warehouse personnel, and transportation providers. Without reliable partners, implementing cross-docking could cause more headaches than it solves.

- Is your current supply chain experiencing delays? If bottlenecks in your supply chain are causing delays in product delivery, cross-docking can streamline operations by minimizing handling and storage time.

- Can your warehouse handle complex operations? Demands precision and efficiency. If your current warehouse struggles with basic logistics, investing in infrastructure might not yield immediate returns.

- Do you have the right technology? Successful implementations depends on real-time data and efficient management systems. If your warehouse is already equipped with advanced technology, adopting may be a smooth transition. If not, the cost of upgrading systems should be factored in.

Frequently Asked Questions About Cross-Docking

Q: What industries benefit the most?

A: Retail, manufacturing, and the food and beverage industries commonly use this. However, any business dealing with perishable goods or requiring fast delivery could benefit.

Q: Can cross-docking be used for all products?

A: No, best suited for perishable goods, high-demand items, and products requiring minimal handling. Products needing special storage conditions or long-term warehousing may not be ideal for cross-docking.

Q: How much does cross-docking cost to implement?

A: The cost depends on factors like the size of your warehouse, the technology required, and the scale of your operations. Initial setup can be costly, but long-term savings are possible through reduced warehousing and transportation costs.

Q: Does cross-docking require specialized technology?

A: Yes, it typically requires advanced inventory management systems and real-time tracking technology to ensure efficient operations. Warehouses must invest in these systems for cross-docking to be effective.

Conclusion

Cross-docking can be a game-changer for warehouses looking to streamline their operations and reduce costs. By minimizing storage time and accelerating product delivery, it offers significant benefits to businesses that require fast, efficient supply chains. However, not every warehouse is suited for cross-docking. It requires careful consideration of product types, supply chain reliability, and technological infrastructure.

If you’re considering this for your warehouse, Lafayette Engineering can help you assess your needs and determine the best solution for your operation. Our expertise in material handling solutions allows us to guide you through the process of integrating cross-docking into your supply chain efficiently and effectively. Contact us today to learn more about how we can help you optimize your warehouse operations.

For more information, visit Lafayette Engineering or connect with us on LinkedIn.