Table of Contents

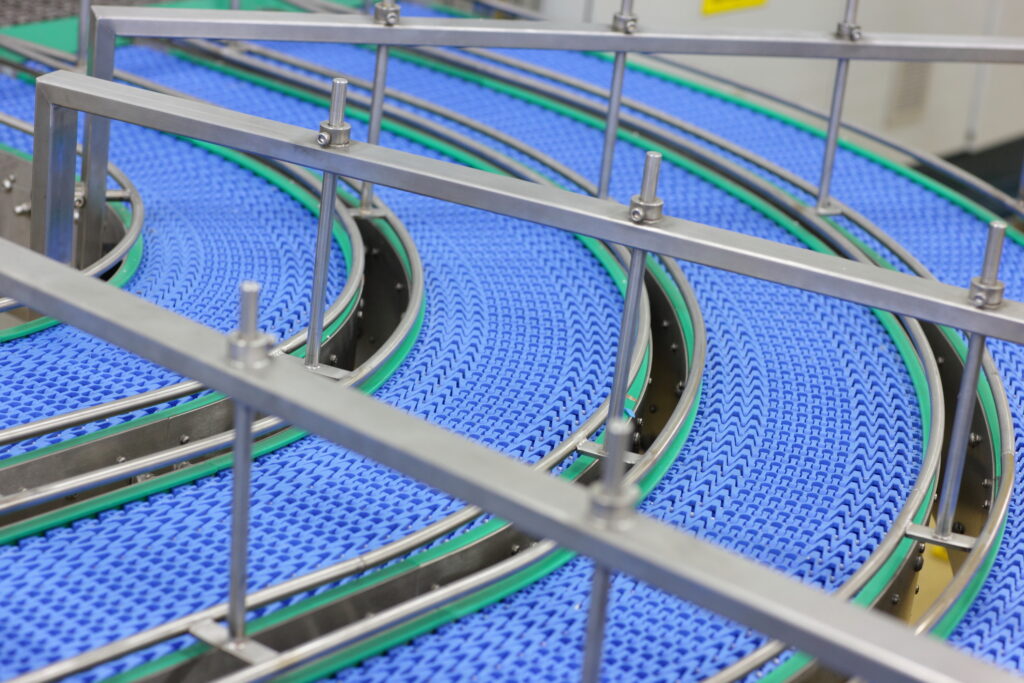

Conveyor system modernization is a crucial step for any business looking to stay competitive and efficient in today’s fast-paced market. By upgrading your conveyor systems, you can significantly enhance productivity, safety, and flexibility, leading to a positive impact on your bottom line. This blog will explore the importance of conveyor system modernization, its benefits, and how Lafayette Engineering can help you achieve these upgrades seamlessly.

Why Conveyor System Modernization Matters

Conveyor systems are the backbone of many industries, facilitating the efficient movement of goods through warehouses, distribution centers, and manufacturing plants. However, as technology advances, older conveyor systems may become less efficient, more prone to breakdowns, and unable to keep up with modern demands. Here are five compelling reasons why conveyor system modernization is essential:

- Increased Efficiency: Modern conveyor systems are designed with the latest technology, ensuring faster and more reliable movement of goods. Upgrading to a modern system can reduce bottlenecks and streamline operations, leading to significant efficiency gains.

- Enhanced Safety: Older conveyor systems may pose safety risks due to outdated designs and lack of modern safety features. Conveyor system modernization includes the implementation of advanced safety measures, reducing the risk of accidents and ensuring a safer working environment for employees.

- Cost Savings: While the initial investment in conveyor system modernization may seem significant, the long-term cost savings are substantial. Modern systems are more energy-efficient, require less maintenance, and have a longer lifespan, resulting in lower operational costs over time.

- Scalability and Flexibility: Modern conveyor systems are highly adaptable, allowing businesses to scale their operations up or down as needed. This flexibility is crucial in responding to changing market demands and business growth.

- Integration with Advanced Technologies: Modern conveyor systems can seamlessly integrate with other advanced technologies such as automation, robotics, and IoT (Internet of Things). This integration enhances overall operational efficiency and provides valuable data insights for continuous improvement.

Key Components of Conveyor System Modernization

Conveyor system modernization involves several key components, each contributing to the overall improvement of your operations. Let’s delve into the essential aspects of upgrading your conveyor systems:

1. Upgrading Conveyor Controls

Modern conveyor systems come with advanced control systems that offer greater precision and reliability. Upgrading your control systems can lead to better synchronization, improved monitoring, and easier troubleshooting.

2. Implementing Advanced Safety Features

Safety is paramount in any industrial setting. Modern conveyor systems are equipped with features such as emergency stop buttons, safety guards, and automated shutdown mechanisms. These enhancements minimize the risk of accidents and ensure compliance with safety regulations.

3. Enhancing Energy Efficiency

Energy efficiency is a significant consideration in conveyor system modernization. Modern systems are designed to consume less energy, reducing your operational costs and environmental footprint. Variable frequency drives (VFDs) and energy-efficient motors are common upgrades that contribute to energy savings.

4. Integrating Automation and Robotics

Automation and robotics are revolutionizing the way conveyor systems operate. By integrating these technologies, you can achieve higher throughput, reduce manual labor, and improve overall efficiency. Automated sorting, picking, and packing systems are examples of how automation can enhance conveyor operations.

5. Utilizing IoT and Data Analytics

The Internet of Things (IoT) and data analytics play a crucial role in modern conveyor systems. Sensors and data collection devices provide real-time insights into system performance, allowing for predictive maintenance and continuous optimization. This data-driven approach ensures that your conveyor system operates at peak efficiency.

Lafayette Engineering: Your Partner in Conveyor System Modernization

When it comes to conveyor system modernization, partnering with an experienced provider like Lafayette Engineering can make all the difference. With a proven track record of delivering high-quality conveyor solutions, Lafayette Engineering offers comprehensive services to upgrade your conveyor systems efficiently and effectively.

Why Choose Lafayette Engineering?

- Expertise and Experience: Lafayette Engineering has extensive experience in designing and implementing modern conveyor systems across various industries. Their team of experts understands the unique challenges and requirements of different businesses, ensuring tailored solutions for optimal results.

- Customized Solutions: Every business is unique, and so are its conveyor system needs. Lafayette Engineering provides customized solutions that align with your specific operational requirements, ensuring a perfect fit for your business.

- Advanced Technology Integration: Lafayette Engineering stays at the forefront of technological advancements, integrating the latest technologies into your conveyor systems. This ensures that your upgraded systems are not only modern but also future-proof.

- Comprehensive Support: From initial consultation to installation and ongoing support, Lafayette Engineering offers end-to-end services to ensure a smooth and successful conveyor system modernization process.

Frequently Asked Questions (FAQ)

1. What is conveyor system modernization?

Conveyor system modernization involves upgrading existing conveyor systems with modern technologies and components to improve efficiency, safety, and reliability. This process can include upgrading controls, implementing safety features, enhancing energy efficiency, and integrating automation and IoT technologies.

2. Why should I consider it?

Modernizing your conveyor system can lead to increased efficiency, enhanced safety, cost savings, scalability, and the ability to integrate advanced technologies. These benefits contribute to improved operational performance and a competitive edge in the market.

3. How long does the process take?

The duration of the modernization process depends on the complexity of the upgrades and the size of your conveyor system. Lafayette Engineering works closely with clients to develop a timeline that minimizes disruptions to operations and ensures a timely completion of the project.

4. What does it cost?

The cost of modernization varies based on the specific upgrades and technologies implemented. While there is an initial investment, the long-term cost savings and efficiency gains make it a worthwhile investment for most businesses.

5. How can Lafayette Engineering help with conveyor system modernization?

Lafayette Engineering offers comprehensive services for conveyor system modernization, including consultation, design, implementation, and ongoing support. Their expertise and experience ensure that your upgraded system meets your operational needs and delivers optimal performance.

Why Pursue Conveyor System Modernization?

Conveyor system modernization is a strategic investment that can significantly enhance your business operations. By upgrading to modern systems, you can achieve higher efficiency, improved safety, and substantial cost savings. Partnering with a trusted provider like Lafayette Engineering ensures a seamless and successful modernization process, positioning your business for long-term success.

For more on how Lafayette Engineering can help your business, follow us on us on LinkedIn!