Table of Contents

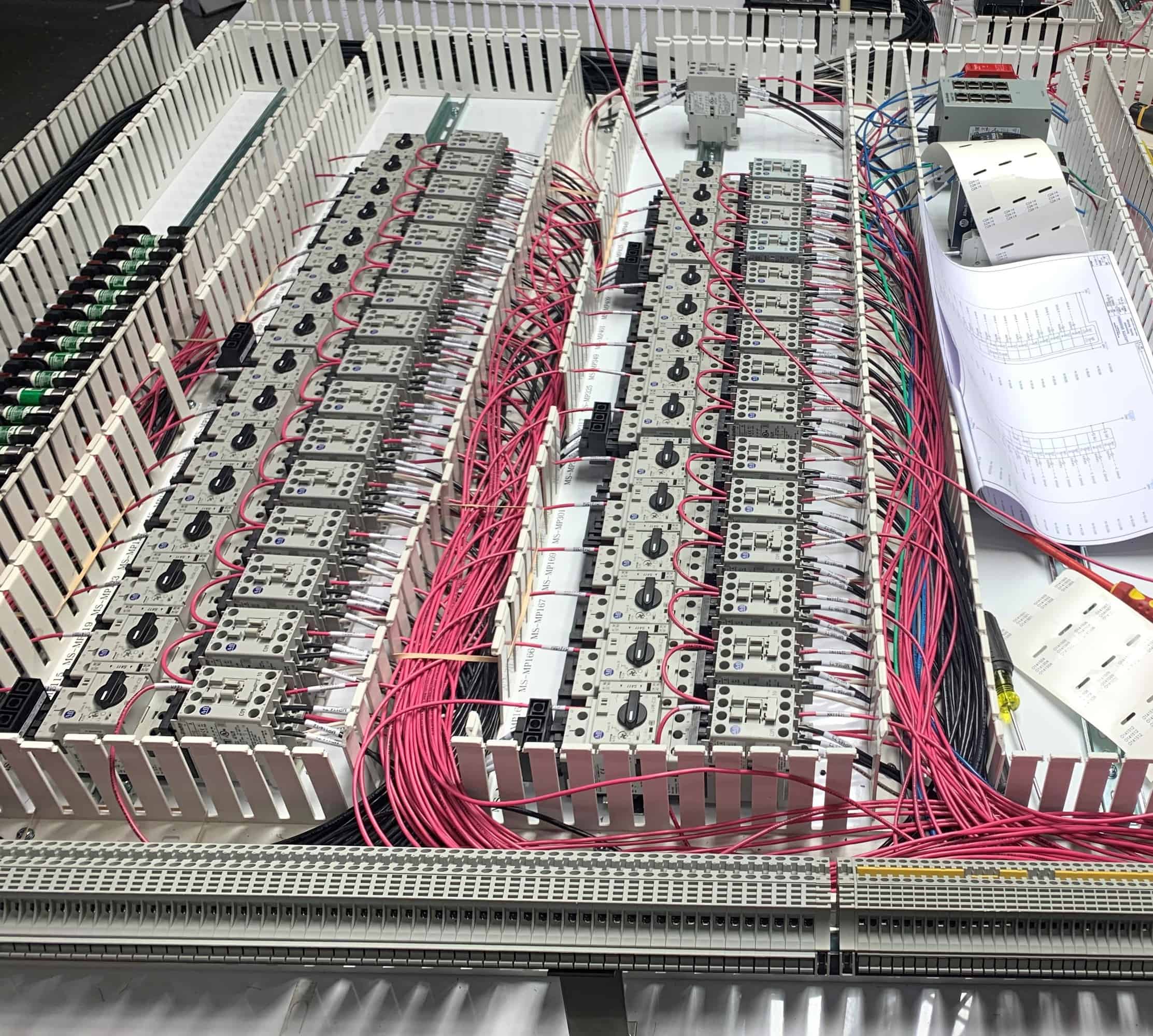

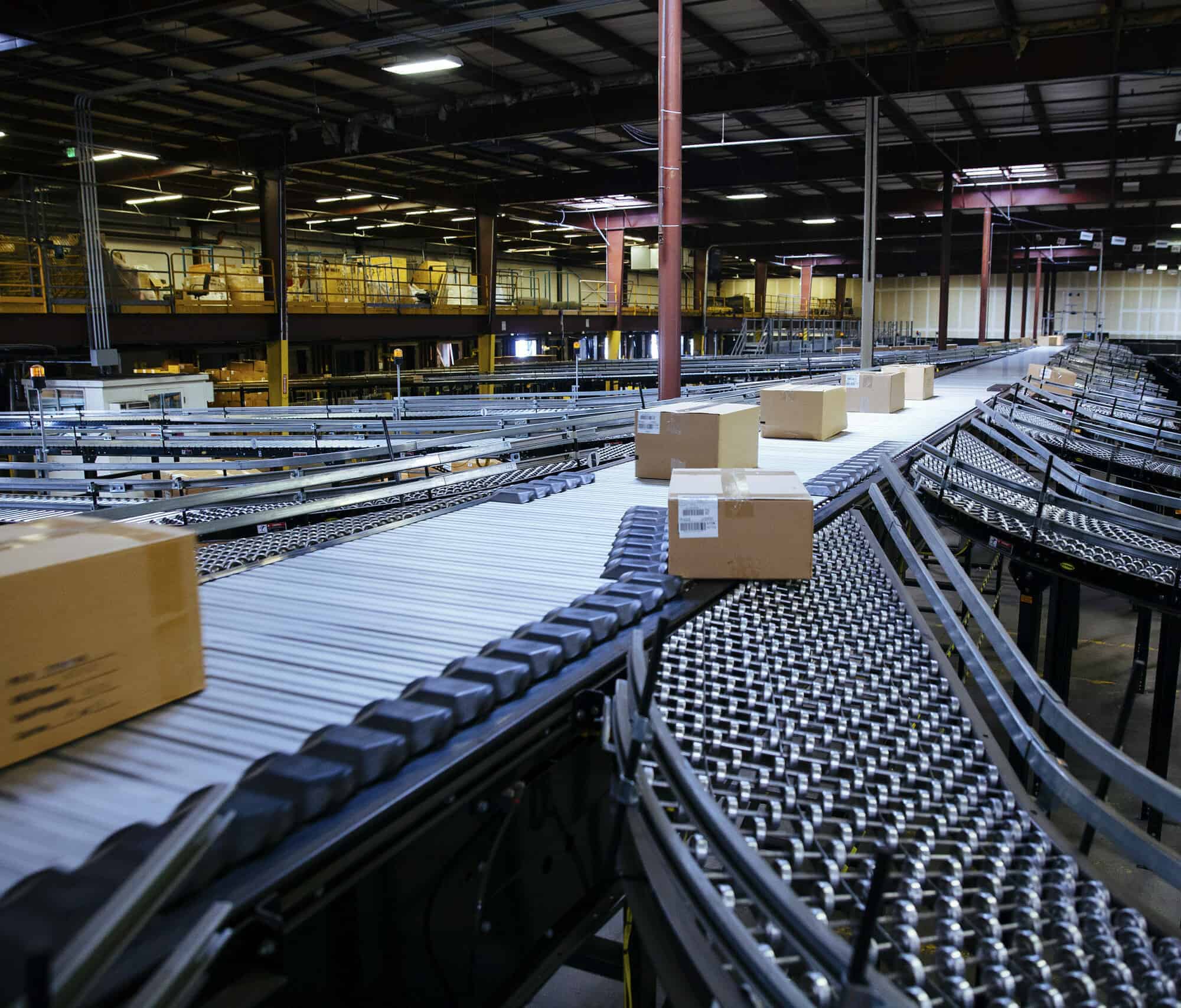

Control Panel Design encompasses the comprehensive process of creating electrical and industrial control panels that serve as the backbone for managing machinery and processes in various industries. These panels are pivotal in ensuring the efficient and safe operation of equipment, offering both control and monitoring capabilities that are essential for modern industrial operations.

The Essence of Control Panel Design

At its core, Control Panel Design is about crafting solutions that meet the specific needs of an industry or project. This involves selecting the right components, designing the layout, and ensuring that the panel meets all regulatory standards for safety and efficiency. The design process is intricate, requiring a deep understanding of electrical engineering, industry standards, and the operational needs of the client.

Types of Control Panels

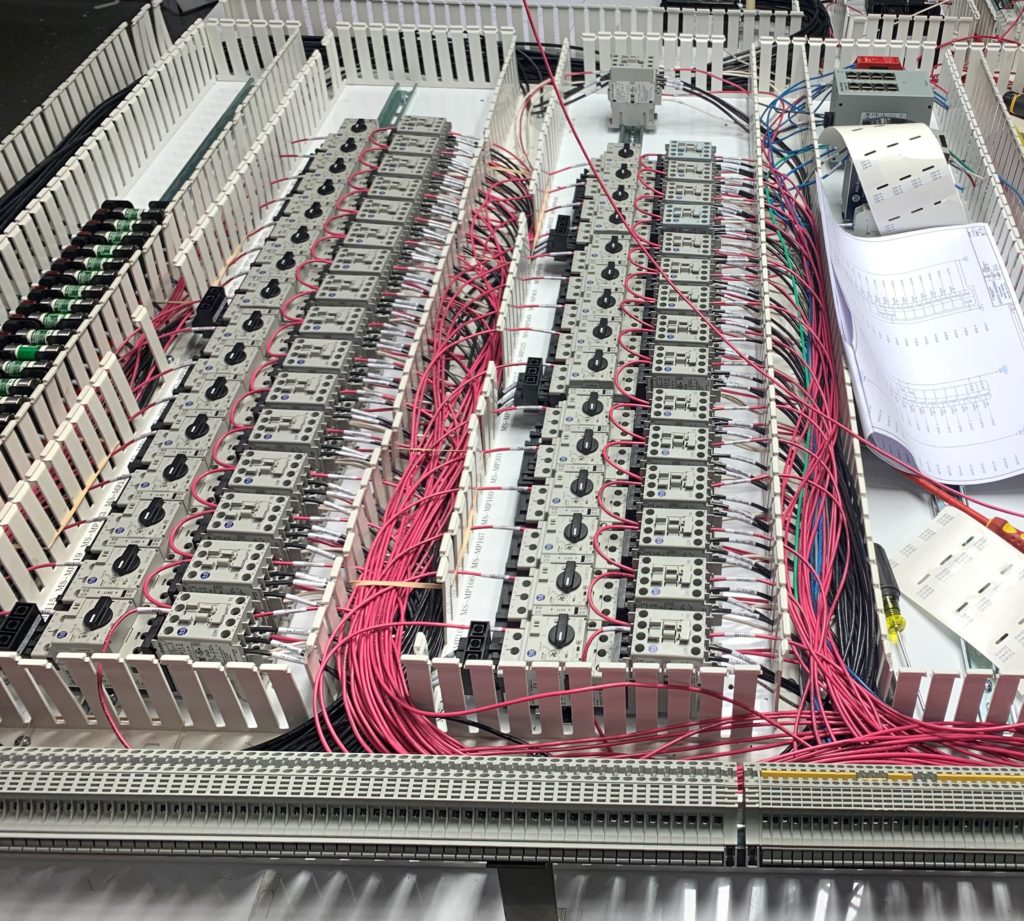

Control panels can vary significantly in complexity and functionality, ranging from simple control stations to sophisticated, multi-panel systems for comprehensive process control. Some common types of control panels include:

- Variable Frequency Drive (VFD) Panels: These control the speed of electric motors by varying the frequency and voltage supplied, offering protection and efficiency.

- Programmable Logic Controller (PLC) Panels: Used for automating machinery, PLC panels allow for flexibility and ease of modification in control logic.

- Network/Communication Panels: These facilitate the integration and communication between various industrial networks.

- Power Distribution Panels (PDP): Essential for distributing power across subsidiary circuits while ensuring overcurrent protection.

- Motor Control Centers (MCCs): Provide centralized control, protection, and isolation for motors.

- Human Machine Interface (HMI) Panels: Allow operators to interact with machinery and processes through a graphical interface.

The Design Process

The design process for control panels involves several critical steps:

- Understanding Requirements: It begins with a thorough understanding of the client’s needs, including the operational environment, machinery to be controlled, and specific industry standards.

- Component Selection: Based on the requirements, appropriate components are selected, considering factors like durability, efficiency, and compliance with standards.

- Layout Design: The physical layout of the panel is designed, ensuring optimal arrangement of components for safety, efficiency, and ease of maintenance.

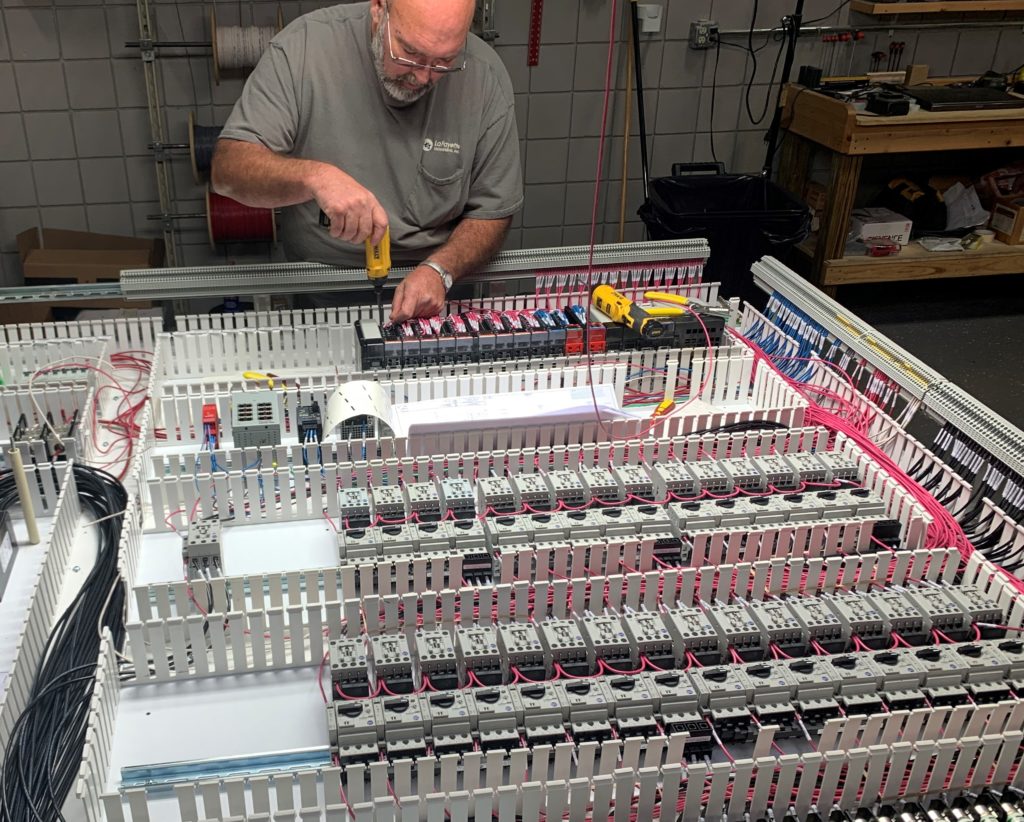

- Wiring and Assembly: With the design in place, the panel is wired and assembled, adhering to strict quality and safety standards.

- Testing: Before deployment, the panel undergoes rigorous testing to ensure it operates as intended and meets all safety requirements.

Why Control Panel Design Matters

In the industrial world, control panels are indispensable. They not only ensure the smooth operation of machinery but also play a crucial role in safety, efficiency, and productivity. A well-designed control panel can significantly reduce the risk of operational failures, enhance system reliability, and streamline processes, leading to substantial cost savings and operational improvements.

Why Lafayette Engineering is the Leader in Control Panel Design

Lafayette Engineering: A Leader in Control Panel Design

In the competitive landscape of Control Panel Design, Lafayette Engineering has carved out a niche for itself through a combination of innovation, quality, and customer-centric approaches. Here’s how Lafayette Engineering differentiates itself from the competition:

Unmatched Expertise

Lafayette Engineering brings together a team of highly skilled engineers and technicians with extensive experience in control panel design. This expertise allows for the development of sophisticated solutions that not only meet but exceed industry standards and client expectations. The team’s deep understanding of the technical and regulatory nuances ensures that every project is executed with precision and excellence.

Customization at Its Core

Understanding that each industry and project has unique requirements, Lafayette Engineering places a strong emphasis on customization. Unlike one-size-fits-all solutions, Lafayette Engineering’s approach is to deeply understand the client’s operational needs, challenges, and goals. This enables the creation of tailored control panels that perfectly align with the specific demands of each application, ensuring optimal performance and efficiency.

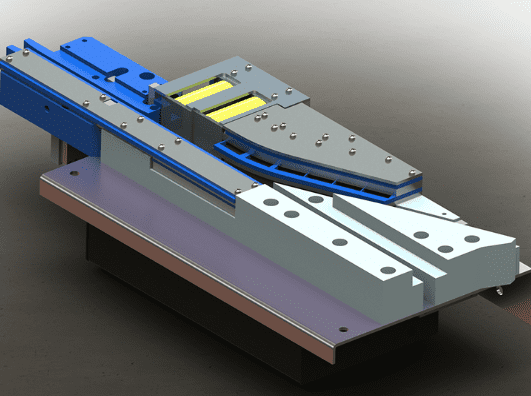

Cutting-Edge Technology

Staying at the forefront of technological advancements is a hallmark of Lafayette Engineering. The company invests in the latest design software, manufacturing techniques, and component technologies to ensure that its control panels are the most advanced on the market. This commitment to technology not only enhances the functionality and reliability of the control panels but also offers clients future-proof solutions that adapt to evolving needs.

Sustainability and Efficiency

Lafayette Engineering is committed to sustainability and efficiency, both in its design practices and the solutions it provides. By incorporating energy-efficient components and designing for minimal environmental impact, Lafayette Engineering’s control panels contribute to reduced operational costs and a smaller carbon footprint for its clients. This approach not only benefits the environment but also offers long-term value to clients through savings and compliance with environmental regulations.

Exceptional Service and Support

What truly sets Lafayette Engineering apart is its dedication to exceptional customer service and support. From the initial consultation to post-installation support, Lafayette Engineering works closely with its clients every step of the way. This partnership approach ensures that projects are completed on time, within budget, and with the functionality that clients need to succeed.

Proven Track Record

Lafayette Engineering’s reputation is built on a foundation of successful projects across a wide range of industries. This proven track record is a testament to the company’s ability to deliver high-quality control panel solutions that meet the complex challenges of modern industrial operations. Clients trust Lafayette Engineering for its reliability, expertise, and commitment to excellence.

Follow us on Linkedin