Table of Contents

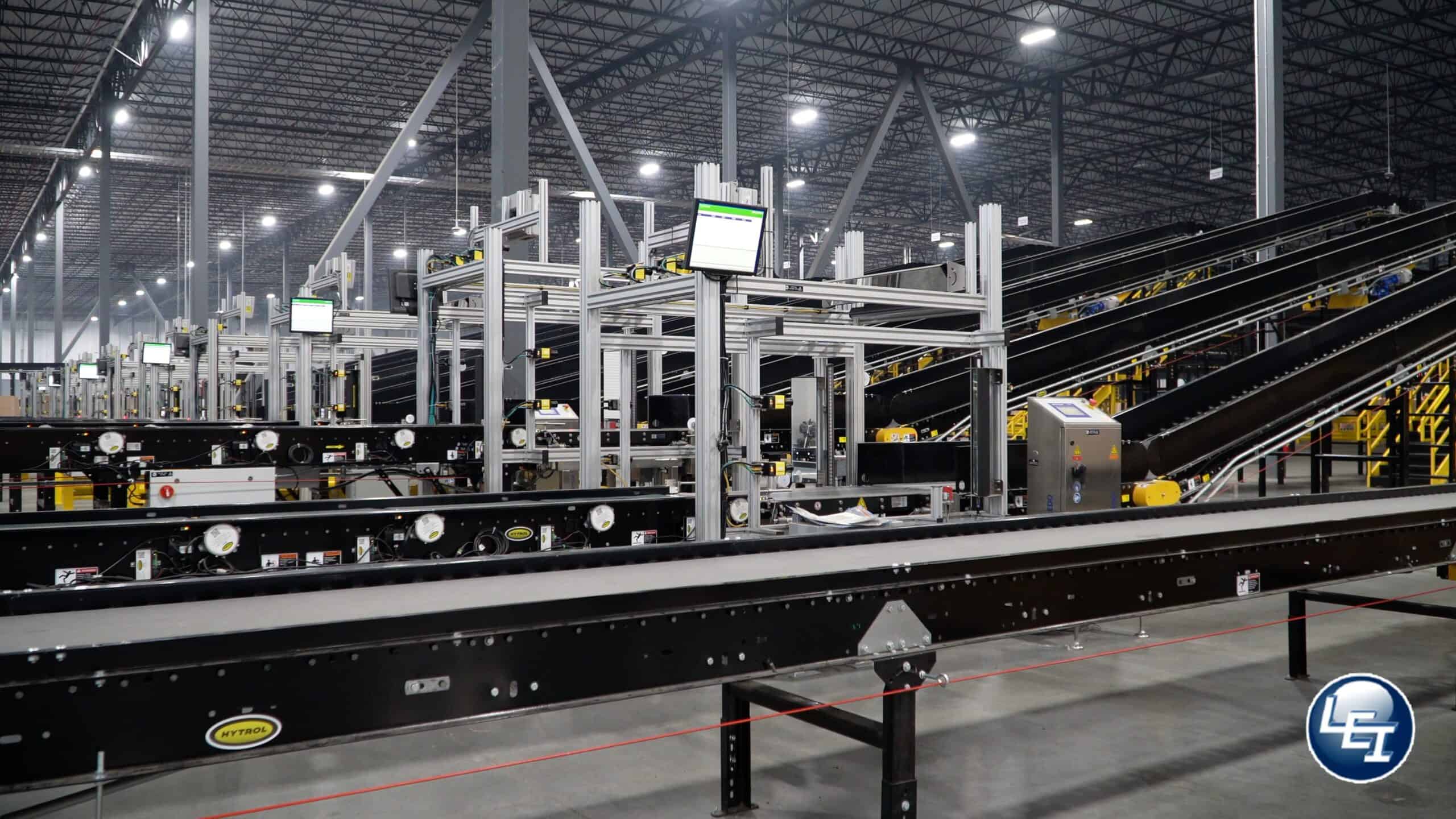

Lafayette Engineering stands out among conveyor installation companies when it comes to efficient, reliable, and expertly executed conveyor system installations. With years of experience and a commitment to excellence, we provide top-tier solutions tailored to meet the diverse needs of our clients across various industries.

Why Choose Lafayette Engineering Among Conveyor Installation Companies?

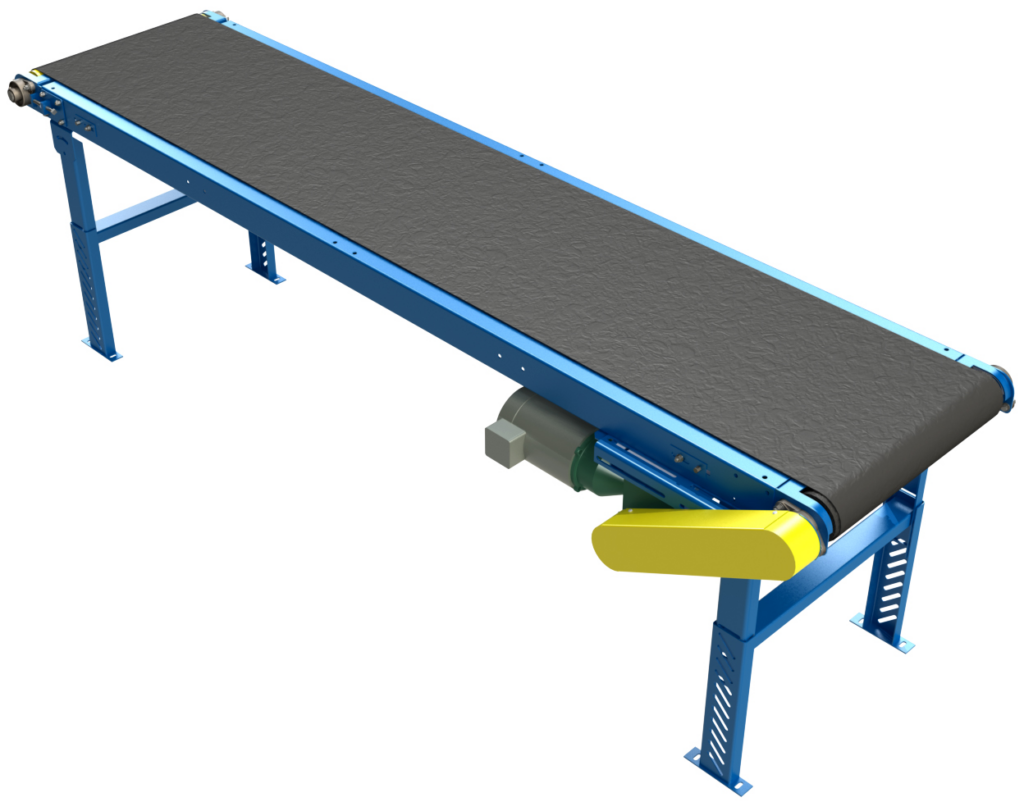

As one of the premier conveyor installation companies, Lafayette Engineering offers comprehensive services that ensure your conveyor systems are installed to the highest standards. Our expertise encompasses:

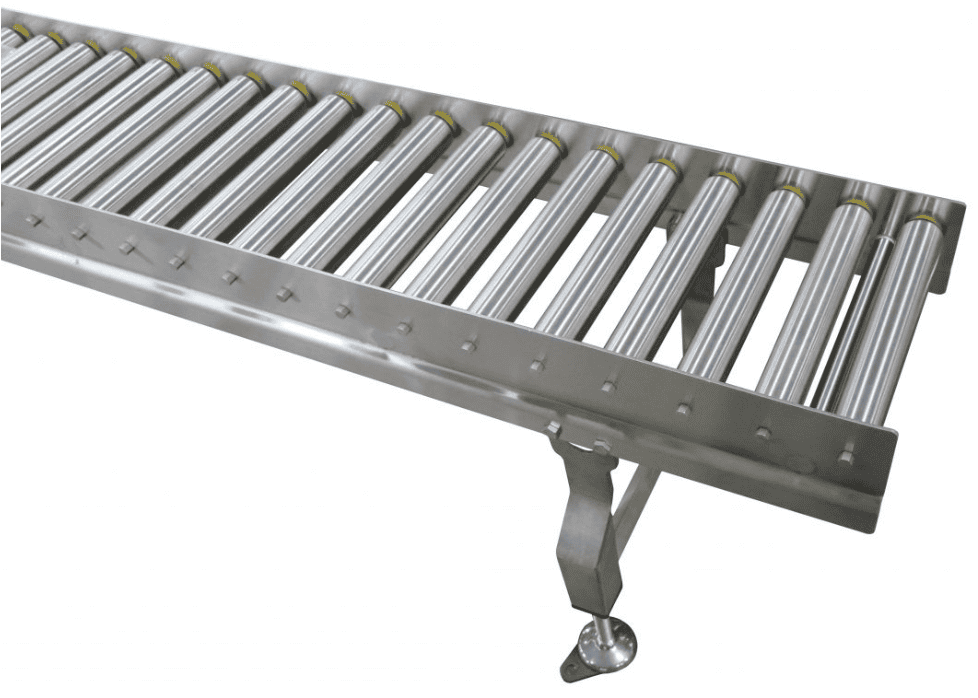

- Customized Solutions: We understand that every facility has unique requirements. Our team works closely with clients to design and install conveyor systems that are perfectly suited to their specific operational needs.

- Experienced Professionals: Our skilled engineers and technicians bring extensive experience to every project, ensuring precision and efficiency in every installation.

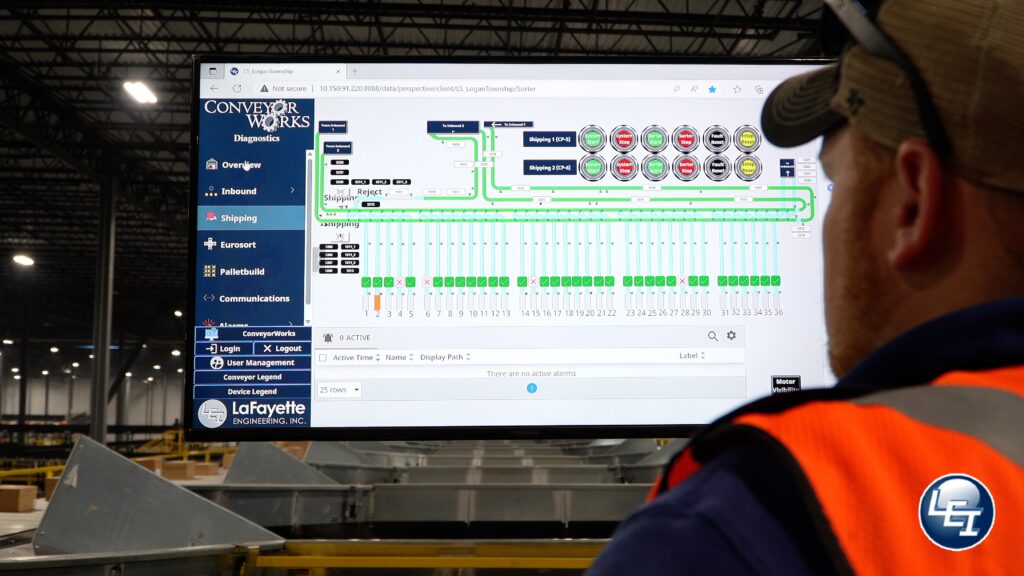

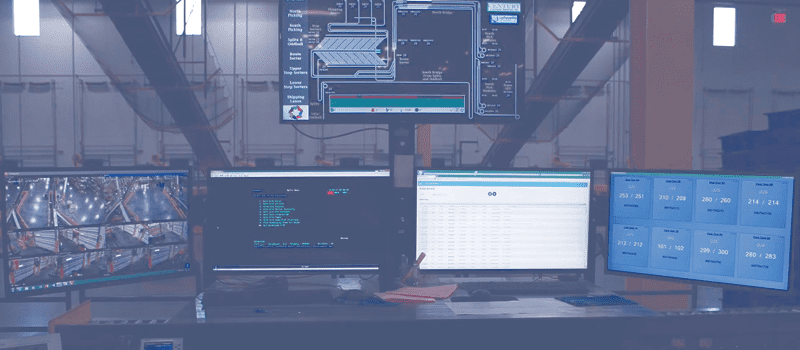

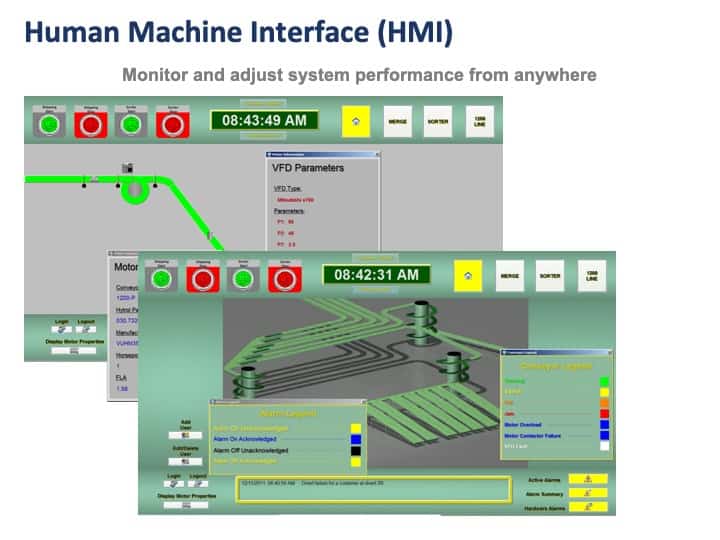

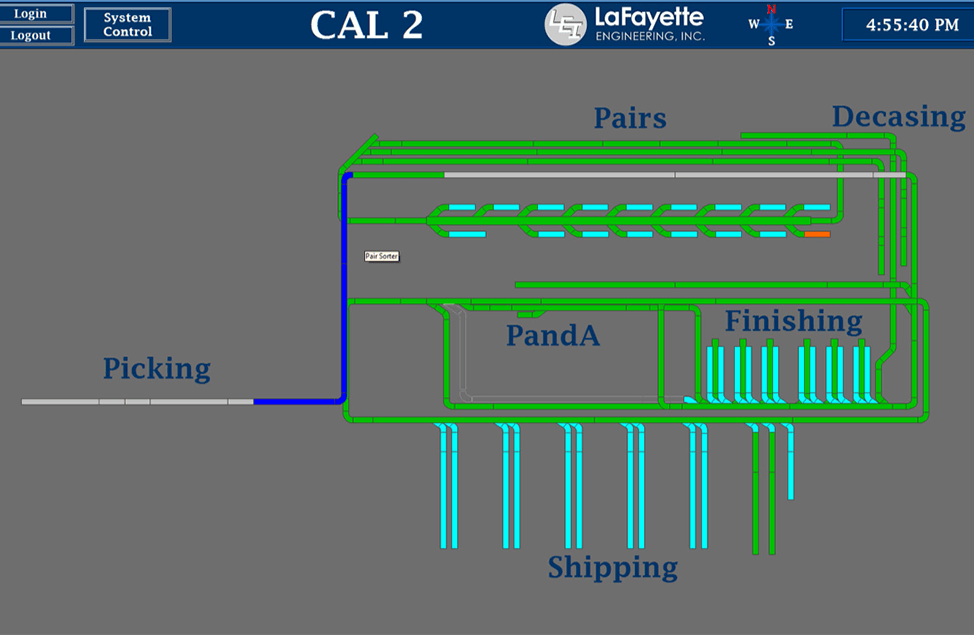

- Advanced Technology: Utilizing the latest technology and industry best practices, Lafayette Engineering ensures that every conveyor system we install is state-of-the-art, enhancing productivity and operational efficiency.

- Comprehensive Service: From initial consultation and design to installation and maintenance, our end-to-end services guarantee seamless integration and long-term performance of your conveyor systems.

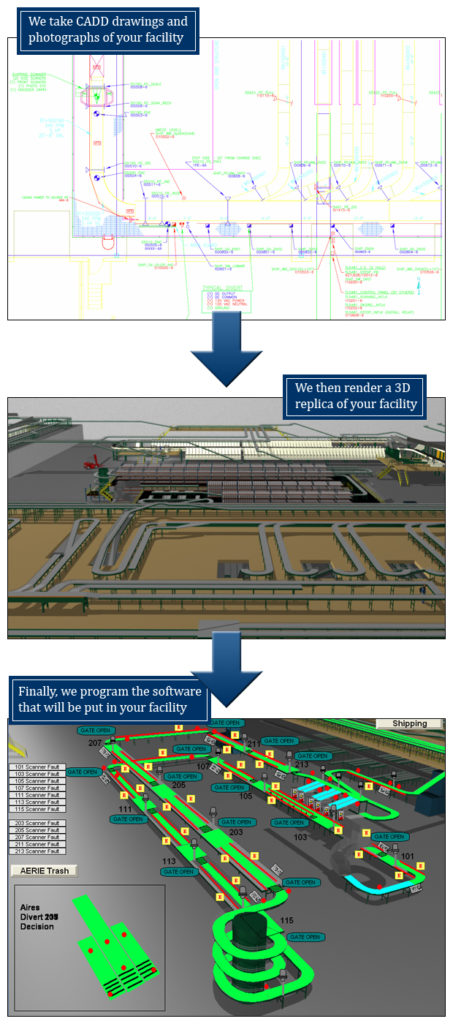

The Lafayette Engineering Process

- Consultation and Planning: We start with a thorough consultation to understand your specific needs and operational challenges. This allows us to design a customized conveyor system that maximizes efficiency and productivity.

- Design and Engineering: Our expert engineers create detailed plans and models, ensuring that every aspect of the conveyor system is optimized for your facility.

- Installation: Our experienced installation teams ensure that the conveyor systems are installed correctly and efficiently, minimizing downtime and disruption to your operations.

- Testing and Commissioning: After installation, we perform rigorous testing to ensure that the system operates flawlessly. We fine-tune the setup to meet your exact requirements, ensuring optimal performance.

- Maintenance and Support: As a leader among conveyor installation companies, Lafayette Engineering offers ongoing maintenance and support services to keep your conveyor systems running smoothly and efficiently.

Industries We Serve

Lafayette Engineering has successfully completed conveyor installations for a wide range of industries, including:

- Manufacturing: Enhancing production lines with reliable and efficient conveyor systems.

- Warehousing and Distribution: Streamlining operations with advanced material handling solutions.

- Automotive: Providing customized conveyor systems for automotive assembly and parts distribution.

- Food and Beverage: Installing hygienic and efficient conveyor systems to meet industry standards.

- E-commerce: Optimizing fulfillment centers with state-of-the-art conveyor solutions.

Why Lafayette Engineering?

As one of the leading conveyor installation companies, Lafayette Engineering is dedicated to providing high-quality, reliable, and customized solutions. Our commitment to excellence, combined with our extensive industry experience, makes us the preferred choice for businesses looking to optimize their operations with advanced conveyor systems.

Contact Us

Ready to elevate your facility’s efficiency with top-notch conveyor installation? Contact Lafayette Engineering today to learn how we can help you achieve your operational goals.

Visit our website for more information and to get started on your next conveyor installation project.

#ConveyorInstallationCompanies #LafayetteEngineering #MaterialHandling #IndustrialAutomation #Manufacturing #Warehousing #Ecommerce #Automotive #FoodAndBeverage

Discover why Lafayette Engineering is a leader among conveyor installation companies. Let us help you streamline your operations and boost productivity with our expert conveyor installation services.

Check out Southern Conveyors article about Lafayette Engineering here