Table of Contents

The material handling industry is constantly evolving, and companies are striving to find new ways to save costs while maintaining efficiency. Whether you are involved in manufacturing, warehousing, or logistics, managing expenses is crucial for a profitable operation. In this blog, we’ll explore five effective ways to save money in the material handling industry, with insights inspired by Plant Services and additional recommendations from Lafayette Engineering.

1. Implement Preventive Maintenance Programs in the Material Handling Industry

One of the most impactful cost-saving strategies is implementing preventive maintenance programs. Regular maintenance on conveyors, automated systems, and other equipment helps to reduce downtime, extend the lifespan of machinery, and prevent unexpected breakdowns. Unplanned downtime not only disrupts production but also results in costly repairs and potential revenue loss.

Why it works: Preventive maintenance identifies potential issues before they escalate into larger, more expensive problems. By scheduling regular checks, lubrication, and parts replacements, businesses can achieve greater system reliability and uptime.

Lafayette Engineering’s Solution: At Lafayette Engineering, we provide comprehensive preventive maintenance services, ensuring that your material handling systems remain operational and efficient. Our expert team conducts routine inspections, thorough diagnostics, and quick repairs to keep your systems running smoothly.

2. Optimize Inventory Management

Inefficient inventory management can lead to increased carrying costs, storage expenses, and wasted resources. Companies should adopt strategies such as real-time tracking, automated inventory systems, and advanced forecasting methods to ensure they only store what’s necessary.

Why it works: Proper inventory optimization reduces the risk of stockouts or overstocking, which directly impacts warehousing costs. Automated systems help improve inventory accuracy, which can lead to improved order fulfillment and better customer satisfaction.

Lafayette Engineering’s Solution: We design and implement cutting-edge inventory management systems that integrate seamlessly with your material handling processes. From automated pick-and-place systems to conveyor integrations, Lafayette Engineering provides technology that streamlines inventory handling.

3. Invest in Energy-Efficient Technologies

Energy costs are a significant expense in material handling operations. By upgrading to energy-efficient machinery and implementing smart energy management practices, companies can significantly reduce their energy bills. Consider investing in energy-efficient motors, variable frequency drives (VFDs), and LED lighting to save money on electricity costs.

Why it works: Energy-efficient technologies often come with lower operating costs and extended service lives. VFDs, for instance, can reduce energy consumption by adjusting motor speeds based on real-time load requirements.

Lafayette Engineering’s Solution: We specialize in retrofitting existing material handling systems with energy-efficient components. Our engineering team evaluates your current setup and suggests upgrades to increase efficiency and reduce costs, all while minimizing disruptions.

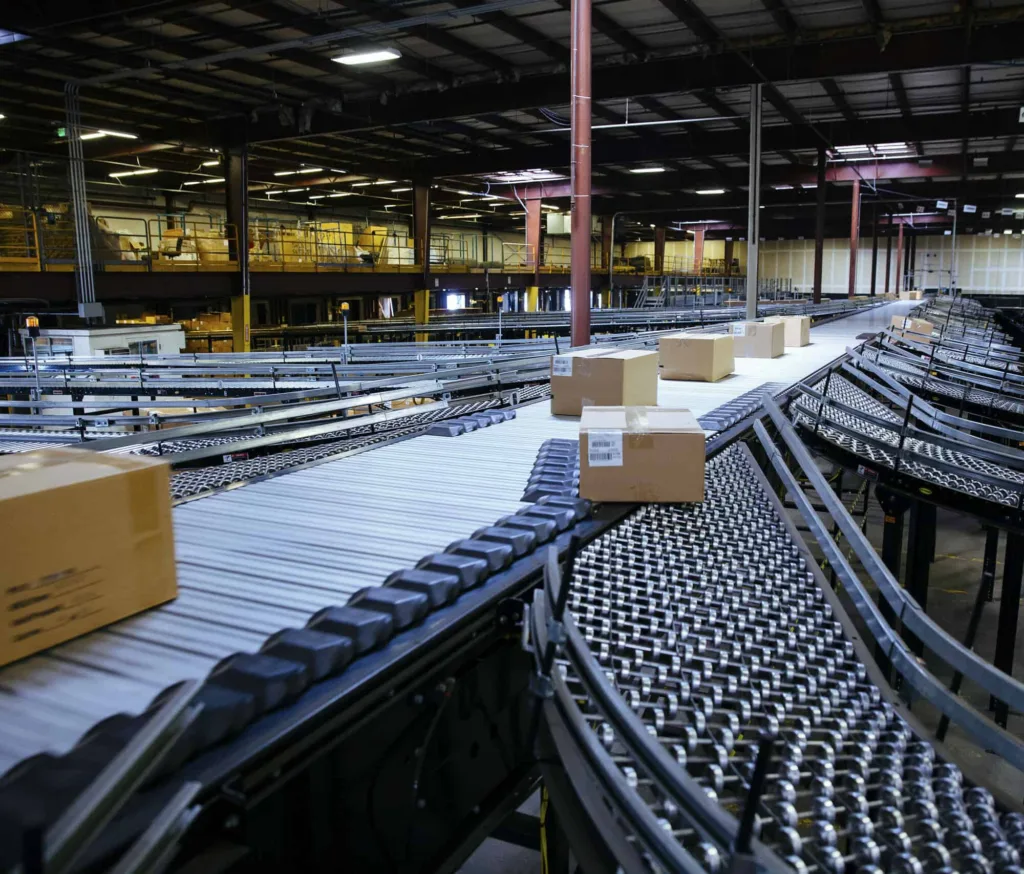

4. Implement Automation and Robotics

Automation and robotics have revolutionized material handling operations by increasing productivity, reducing labor costs, and improving safety. Automated guided vehicles (AGVs), robotic arms, and conveyor systems allow businesses to move goods efficiently with minimal human intervention.

Why it works: Automation reduces human error, enhances precision, and increases throughput. While the initial investment might be high, the long-term cost savings from improved productivity and lower labor expenses can be substantial.

Lafayette Engineering’s Solution: We offer tailored automation solutions, from fully integrated conveyor systems to robotic handling applications. Our goal is to provide innovative designs that maximize efficiency and save on operational costs.

5. Train Employees on Best Practices

Well-trained employees are key to an efficient material handling operation. Companies should invest in regular training programs to keep their workforce updated on the latest technologies, safety protocols, and operational best practices.

Why it works: A trained workforce not only reduces the risk of workplace accidents but also ensures optimal equipment handling, leading to lower maintenance costs and improved system longevity.

Lafayette Engineering’s Solution: We provide specialized training programs for our clients’ staff, covering best practices in material handling, safety protocols, and the efficient use of systems. Our team works closely with your workforce to ensure they are confident in operating the equipment.

Why Choose Lafayette Engineering?

At Lafayette Engineering, we are dedicated to providing cost-effective and reliable solutions tailored to your unique needs. We work closely with our clients to design, implement, and maintain advanced material handling systems that drive efficiency and reduce costs. From automated systems and inventory management solutions to preventive maintenance and training, we offer end-to-end services that elevate your operations.

Our Commitment to Efficiency

Lafayette Engineering prides itself on delivering innovative solutions that help businesses thrive in the competitive material handling industry. We are committed to using the latest technologies and engineering practices to create systems that save money, reduce energy consumption, and increase overall productivity.

Connect with Us: Ready to improve your material handling systems and save on operational costs? Contact Lafayette Engineering today for a consultation. Visit our website or connect with us on LinkedIn.

By implementing these five effective strategies, companies in the material handling industry can significantly save costs while improving their overall operational efficiency. Lafayette Engineering is here to support you in every step of the process, offering expert guidance and state-of-the-art solutions that help you achieve your goals.