Table of Contents

LaFayette Engineering, Inc., headquartered in Danville, Kentucky, is a distinguished leader in the field of mechanical installation services, particularly for material handling systems. With a comprehensive suite of offerings, the company ensures that clients receive end-to-end solutions tailored to their specific needs.

Comprehensive Mechanical Installation Services

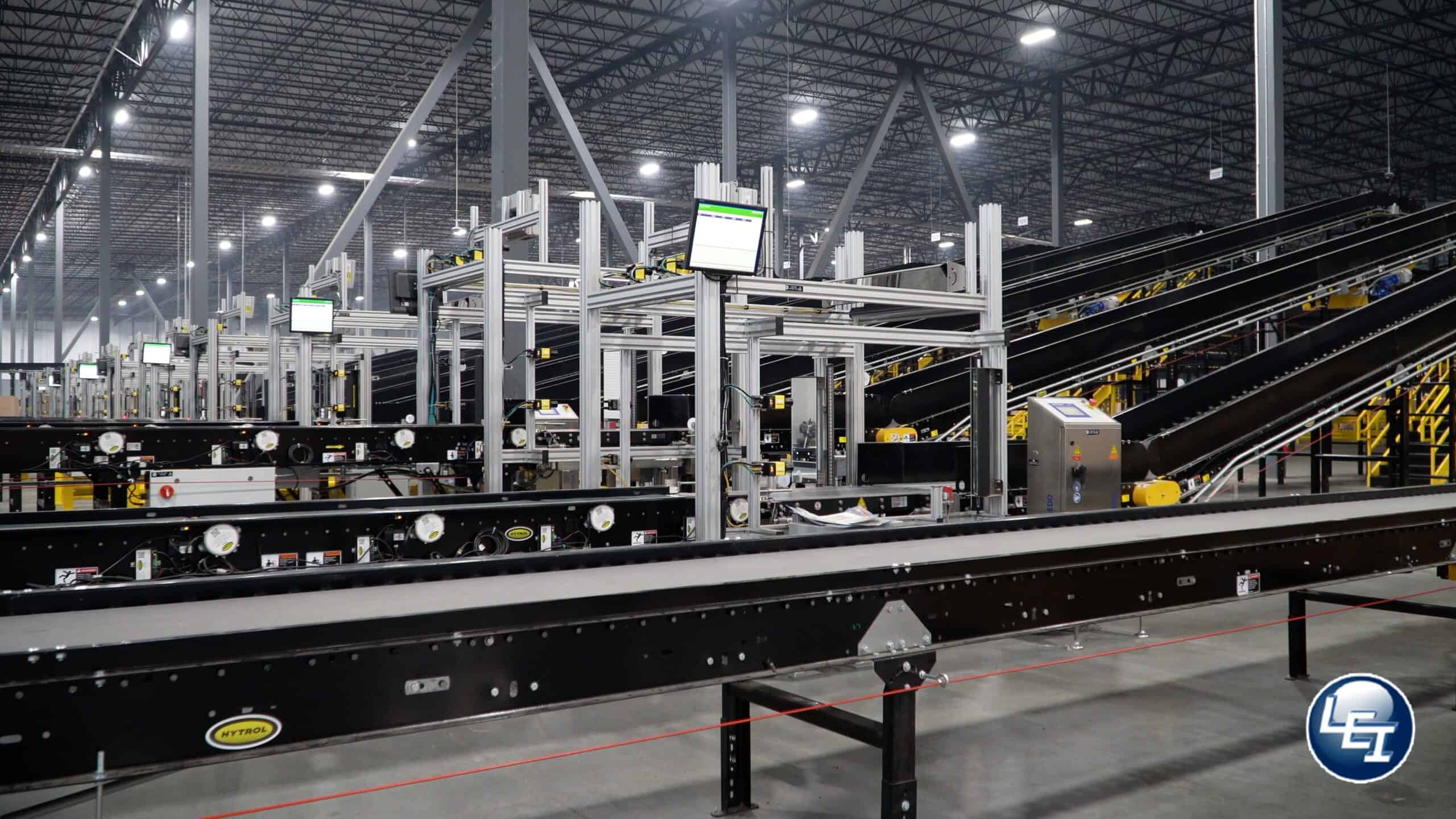

LaFayette Engineering provides a full spectrum of services encompassing the installation, repair, and maintenance of conveyor systems integral to material handling operations. Their expertise extends to engineering, mechanical, electrical, and construction services, ensuring that every project phase is executed with precision. The company’s teams are adept at installing, relocating, and liquidating racks, conveyors, and various types of warehouse equipment. This versatility allows them to mobilize crews promptly to any location, meeting clients’ scheduling and logistical requirements.

Project Management Excellence

Managing warehouse installations, tear-outs, or relocations involves coordinating multiple tasks, which can become complex. LaFayette Engineering’s skilled project managers oversee all aspects of a project, ensuring seamless collaboration among engineers, contractors, and inspectors. This holistic approach guarantees that projects are completed efficiently, on time, and within budget.

Commitment to Quality and Reliability

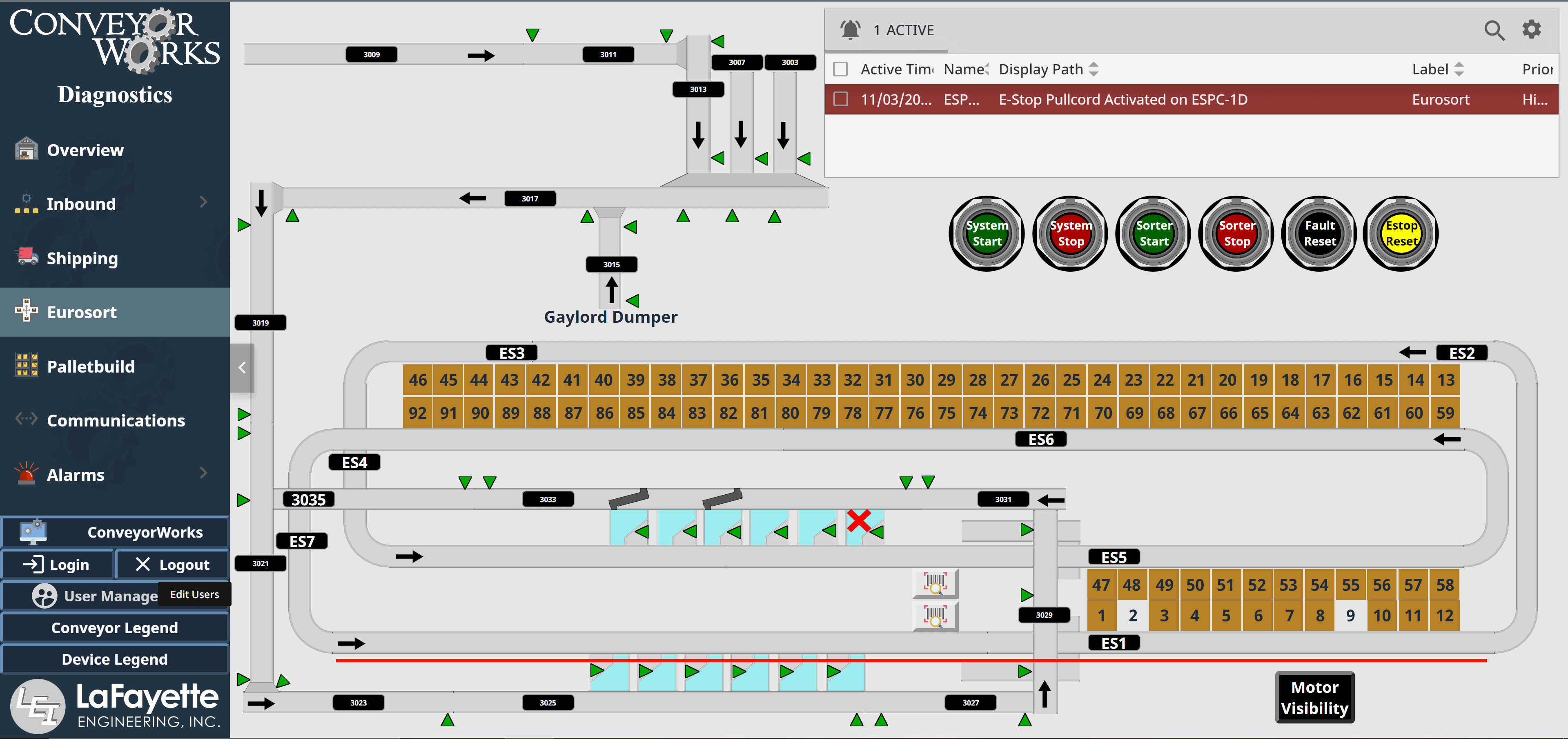

The company places a high value on quality and reliability, recognizing these elements as the cornerstones of success and longevity in the industry. Their highly trained staff delivers design and implementation services with the professionalism and integrity clients deserve. By maintaining open and consistent communication from initial planning through to final testing, LaFayette Engineering ensures that client expectations are not only met but exceeded.

Integrated Services Offering

One of the standout features of LaFayette Engineering is their ability to serve as a single point of contact for comprehensive material handling solutions and project management. They meticulously analyze client requirements, select appropriate equipment, and combine these elements with experienced installation services to deliver cohesive and efficient systems.

Mechanical Design and Engineering Expertise

Utilizing advanced tools like AutoCAD, LaFayette Engineering’s experienced systems engineers produce detailed and accurate designs tailored to each project. This meticulous attention to detail ensures that all mechanical components integrate seamlessly within the client’s operational framework, optimizing performance and efficiency.

Comprehensive Installation Services

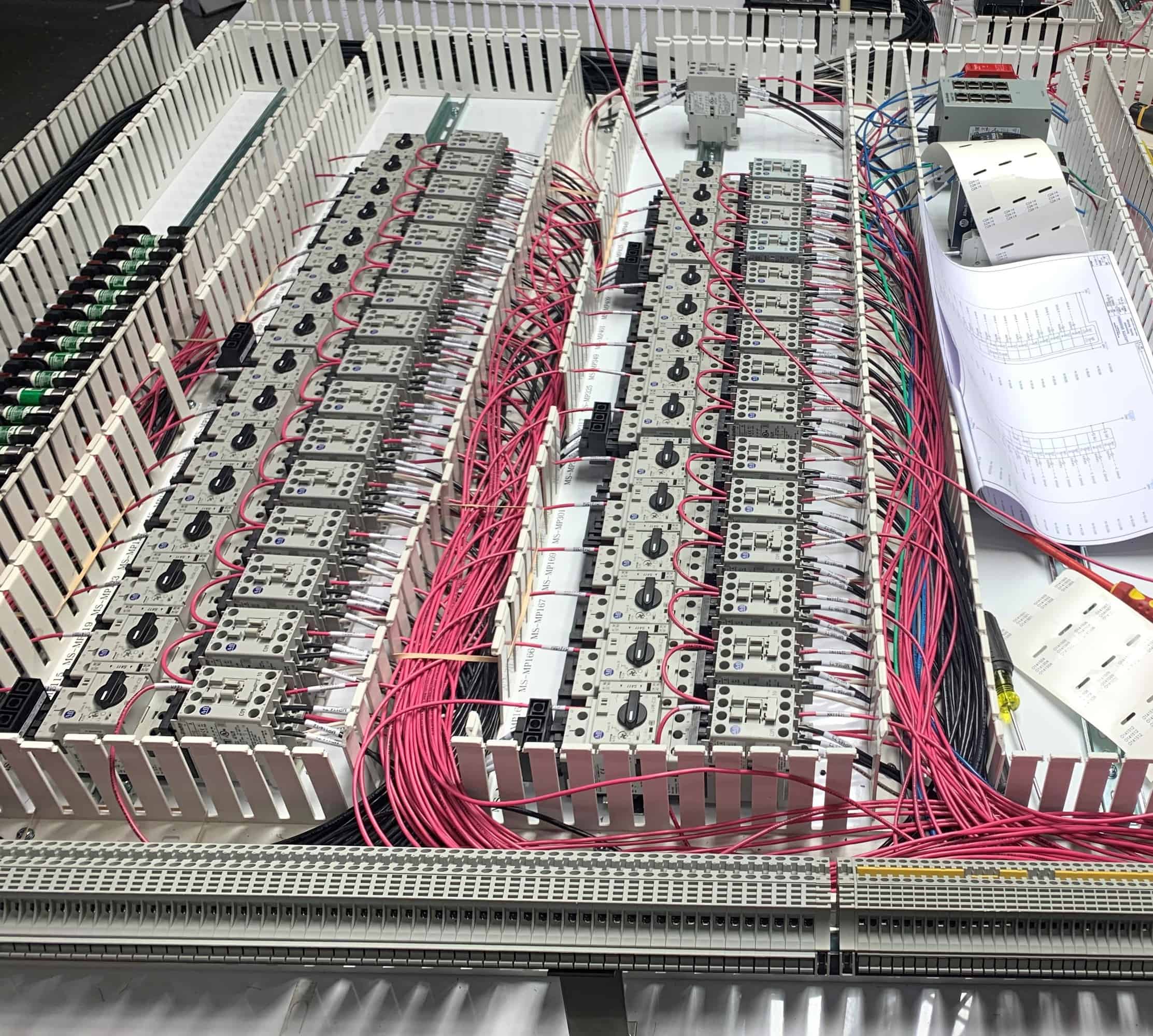

The company’s installation capabilities are extensive, covering both floor-supported and ceiling-hung conveyors, air compressor equipment, air piping systems, pallet racks, and shelving. Additionally, they offer complete electrical field wiring services executed by experienced, licensed electricians. This includes the placement of control panels and wiring of remote electrical devices, ensuring that all systems function harmoniously.

Consulting and Advisory Services

Beyond installation, LaFayette Engineering provides consulting services for new facilities and offers recommendations for improvements to existing installations. Their expertise enables clients to optimize their material handling systems, enhancing efficiency and productivity.

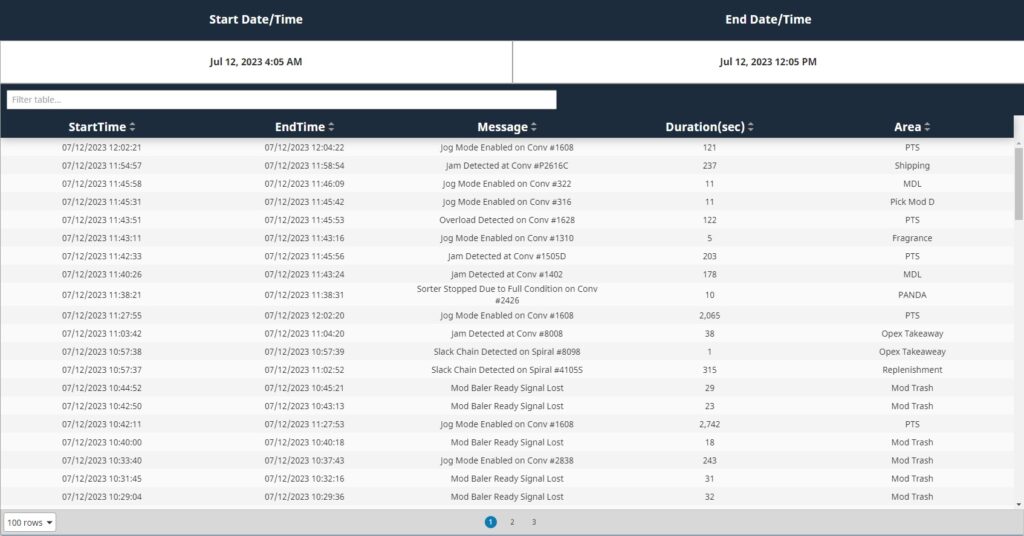

Equipment Tear-Outs, Retrofits, and Preventative Maintenance

The company is proficient in mechanical and electrical services required for tearing out, retrofitting, or relocating existing equipment. They also conduct thorough system inspections and prepare detailed plans outlining necessary preventative maintenance services. This proactive approach helps clients maintain optimal system performance and longevity.

Supply of Replacement Parts

Understanding the critical nature of minimizing downtime, LaFayette Engineering assists in identifying and supplying replacement parts for equipment. Their prompt and efficient service ensures that clients’ operations continue with minimal disruption.

Client-Centric Approach

LaFayette Engineering’s client-centric philosophy is evident in their commitment to providing maximum quality, productivity, and reliability at the lowest possible cost. By offering a comprehensive suite of services under one roof, they eliminate the need for clients to engage multiple companies, simplifying project management and ensuring accountability.

Conclusion – Mechanical Installation Services

In the realm of mechanical installation services for material handling systems, LaFayette Engineering, Inc. stands out as a leader. Their comprehensive service offerings, commitment to quality, and client-focused approach make them a preferred partner for businesses seeking reliable and efficient solutions. By entrusting their projects to LaFayette Engineering, clients can be confident in receiving services that not only meet but often exceed industry standards, ensuring the success and longevity of their operations.