Table of Contents

Lafayette Engineering has established itself as a leader in electrical installation controls and industrial automation since its founding in 1989. Based in Danville, Kentucky, with additional offices in California and New Jersey, the company offers comprehensive electrical installation services focused on conveyor systems and industrial controls. This comprehensive guide addresses the most common questions clients have about Lafayette Engineering’s electrical installation services.

Frequently Asked Questions About Lafayette Engineering’s Electrical Installation Services

What is Lafayette Engineering’s core business focus?

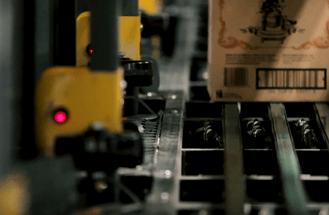

Lafayette Engineering specializes in the design and installation of electrical controls for conveyor systems, with particular expertise in high-speed case sortation for warehouses and distribution centers. The company combines the technical capabilities and expertise typically associated with large engineering firms while offering the flexibility, personalized service, and affordability of a smaller company.

What sets Lafayette Engineering apart from other electrical installation providers?

Lafayette Engineering offers a unique “one-stop-shop” approach to projects. All work is completed in-house, from conception to installation and support, which means clients receive ONE QUOTE and enjoy more lenient lead times. This integrated approach results in cost savings and faster installation times compared to working with multiple vendors.

What types of electrical installation services does Lafayette Engineering offer?

Lafayette Engineering provides a comprehensive range of electrical installation services for industrial environments, including:

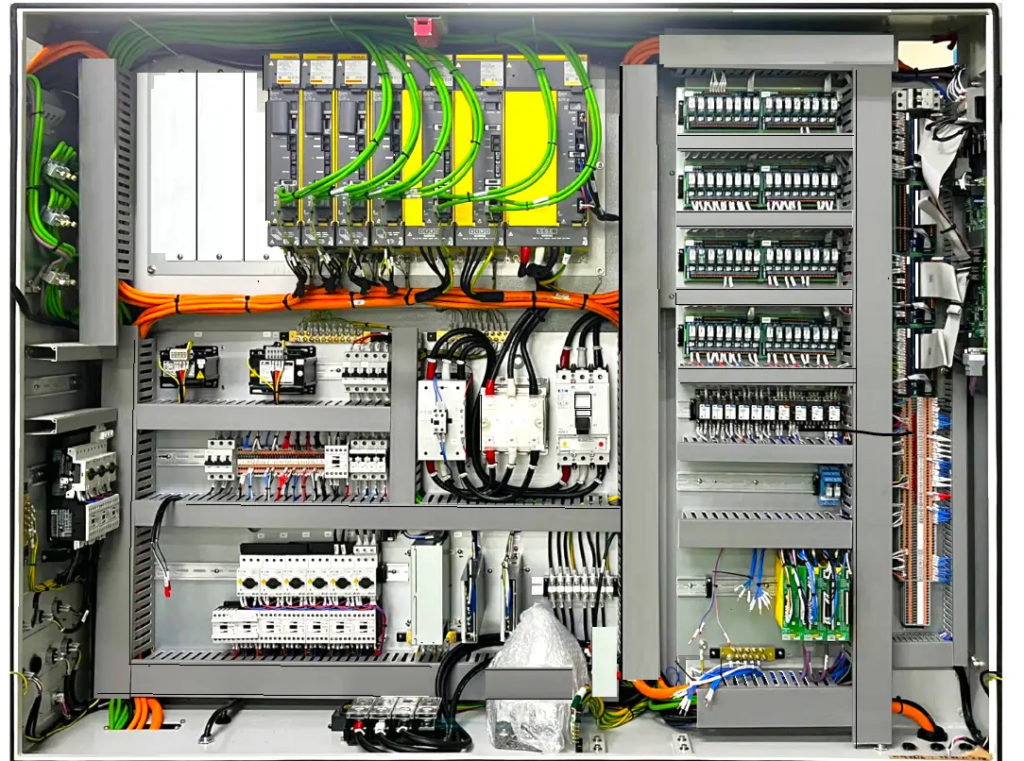

- Controls System Installation: Implementation of PLC (Programmable Logic Controller) systems and advanced control architectures

- Electrical Field Wiring: Complete field wiring services executed by licensed electricians

- Control Panel Design and Installation: Custom control panel solutions for various industrial applications

- Human Machine Interface (HMI) Implementation: Installation of user-friendly interfaces for system operation

- System Integration: Seamless integration of electrical controls with mechanical conveyor systems

- Warehouse Control Systems: Installation of comprehensive control solutions for entire warehouse operations

- High-Speed Sortation Systems: Specialized electrical installations for sorting applications

What industries does Lafayette Engineering serve?

Lafayette Engineering primarily serves the material handling and warehouse automation industries. Their electrical installation services benefit clients in:

- Distribution centers

- E-commerce fulfillment centers

- Manufacturing facilities

- Retail supply chain operations

- Logistics companies

- Warehouse operations

How does Lafayette Engineering ensure quality in their electrical installations?

Lafayette Engineering maintains high standards for quality through several approaches:

- Component Selection: Using only non-proprietary components from recognized industry leaders

- Experienced Team: Employing skilled electrical engineers and licensed electricians

- Testing Procedures: Conducting thorough testing before, during, and after installation

- Industry Standards Compliance: Adhering to all relevant electrical codes and safety regulations

- In-House Test Loop: Utilizing their dedicated testing facility to verify system performance before on-site implementation

What is the process for Lafayette Engineering’s electrical installation projects?

Lafayette Engineering follows a systematic approach to electrical installation projects:

- Initial Consultation: Understanding the client’s specific requirements and objectives

- Customized Solution Design: Developing tailored electrical system designs

- Detailed Quoting: Providing comprehensive and transparent project quotes

- Component Procurement: Sourcing high-quality electrical components

- Control Panel Fabrication: Building custom control panels in their fabrication shop

- On-Site Installation: Professional installation by experienced technicians

- System Testing: Thorough testing to ensure proper functionality

- Training and Handover: Educating client personnel on system operation

- Ongoing Support: Providing 24/7 remote support after installation

Does Lafayette Engineering offer electrical maintenance services?

Yes, Lafayette Engineering provides ongoing maintenance and support services for the electrical systems they install. This includes:

- Preventive maintenance programs

- Emergency troubleshooting and repairs

- System upgrades and modifications

- Remote diagnostic support

- Component replacement

How does Lafayette Engineering handle electrical system modifications or upgrades?

Lafayette Engineering offers comprehensive conveyor modification services that include electrical system updates. Their process involves:

- System Audit: Conducting a thorough evaluation of the existing electrical infrastructure

- Improvement Identification: Determining opportunities for enhanced performance

- Component Upgrades: Replacing worn parts or installing newer, more efficient components

- Control System Updates: Implementing the latest control technologies

- System Expansion: Adding new electrical components to support expanded operations

What geographic areas does Lafayette Engineering serve?

Lafayette Engineering provides electrical installation services nationwide with offices strategically located to serve clients across the United States:

- Headquarters in Danville, Kentucky

- West Coast office in the greater Los Angeles area (established 2017)

- East Coast operations through Century Conveyor in South Plainfield, New Jersey

This coast-to-coast presence allows them to offer prompt, localized service to clients throughout the country.

What makes Lafayette Engineering’s electrical control systems unique?

Lafayette Engineering’s electrical control systems stand out for several reasons:

- Open Architecture: Using non-proprietary components and programming for future flexibility

- Customization: Tailored solutions designed for each client’s specific needs

- Integration Capabilities: Seamless connection with existing systems and equipment

- Scalability: Designs that accommodate future expansion

- Remote Support: 24/7 assistance from actual engineers, not automated systems

How does Lafayette Engineering ensure safety in their electrical installations?

Safety is paramount in Lafayette Engineering’s electrical installations. They ensure safety through:

- Strict adherence to all relevant electrical codes and standards

- Proper component selection and installation techniques

- Comprehensive testing protocols

- Built-in safety features and fail-safes

- Thorough documentation and training

What benefits can clients expect from Lafayette Engineering’s electrical installation services?

Clients who choose Lafayette Engineering for their electrical installation needs typically experience:

- Improved operational efficiency

- Reduced downtime and maintenance issues

- Enhanced system performance and reliability

- Lower long-term operational costs

- Simplified project management through their single-source approach

- Access to ongoing technical support and expertise

How does Lafayette Engineering stay current with electrical technology advancements?

Lafayette Engineering maintains its position at the forefront of industrial electrical technology through:

- Continuous research and development efforts

- Investment in advanced testing facilities

- Ongoing professional development for their engineering team

- Partnerships with leading component manufacturers

- Regular industry participation and knowledge exchange

What testimonials or success stories demonstrate Lafayette Engineering’s electrical installation expertise?

Lafayette Engineering has completed numerous successful electrical installation projects across various industries. While specific client names may be confidential, their portfolio includes:

- High-speed sortation systems for major distribution centers

- Comprehensive warehouse control system implementations

- Complex conveyor system electrical installations

- Industrial automation upgrades and retrofits

How can potential clients engage Lafayette Engineering for electrical installation services?

Interested clients can initiate the process by:

- Contacting Lafayette Engineering via their website contact form

- Calling their office directly to discuss project requirements

- Requesting an initial consultation and site assessment

- Obtaining a detailed project quote

- Scheduling a meeting with their electrical engineering team

Conclusion

Lafayette Engineering offers industry-leading electrical installation services with a focus on conveyor systems and industrial controls. Their integrated approach, technical expertise, and commitment to quality have established them as a trusted partner for businesses seeking reliable, efficient, and customized electrical solutions. With a nationwide presence and over three decades of experience, Lafayette Engineering continues to set the standard for excellence in industrial electrical installations.

For more information about Lafayette Engineering’s services or to discuss your specific project needs, visit their website or contact their electrical engineering team directly.