Choosing the right sortation conveyor system can be a complex decision, especially with so many options available. Whether you’re upgrading an existing system or installing one for the first time, it’s essential to understand how these automated solutions can enhance your warehouse’s efficiency, accuracy, and overall performance. To help you make an informed decision, we’ve compiled answers to some of the most frequently asked questions about sortation conveyors. From types of systems to key benefits and maintenance, this FAQ will guide you through everything you need to know.

1. What is a sortation conveyor system?

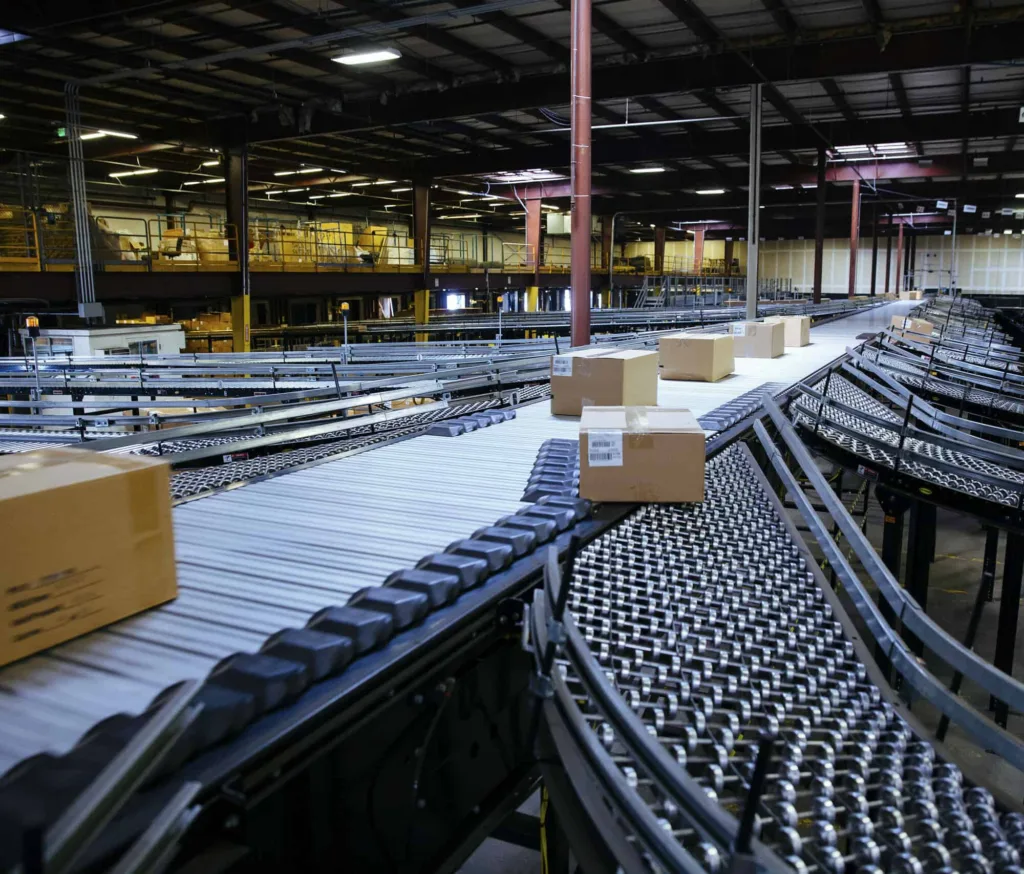

A sortation conveyor system is an automated solution used to identify, track, and direct products or packages to specific locations within a warehouse or distribution center. These systems utilize technology like barcodes, RFID, or sensors to route products based on their destination, helping to streamline the sorting process and reduce manual labor.

2. What are the benefits of using a sortation conveyor system?

The primary benefits of a sortation conveyor system include:

Increased efficiency: Faster movement and sorting of products through your facility.

Improved accuracy: Automated identification and routing minimize human errors.

Cost savings: Reduced labor costs and enhanced productivity over time.

Scalability: Systems can be expanded to meet growing business needs.

Enhanced customer satisfaction: Faster, more accurate order fulfillment leads to better service.

3. What types of sortation conveyors are available?

The most common types of sortation conveyors include:

Sliding Shoe Sorters: High-speed, accurate sorting for diverse products.

Tilt Tray Sorters: Ideal for handling a wide range of product sizes with gentle handling.

Cross-Belt Sorters: Accurate sorting for irregularly shaped items, perfect for e-commerce.

Pop-Up Wheel Sorters: A compact, cost-effective solution for lower-volume operations.

4. How do I know which sortation system is right for my operation?

Choosing the right system depends on several factors:

Throughput: How many items you need to sort per hour.

Product variety: The size, weight, and shape of the products.

Available space: Some systems require more room than others.

Budget: The upfront cost vs. long-term savings and benefits.

Growth potential: Choose a system that can scale as your business grows.

5. What industries use sortation conveyors?

Sortation conveyors are widely used in industries such as:

E-commerce and retail: For high-volume order fulfillment and quick delivery.

Logistics and distribution: To manage large quantities of goods for shipping and storage.

Manufacturing: For directing materials and products to different stages of production.

Postal and parcel services: To efficiently sort and direct packages to their correct destinations.

6. Can sortation conveyors handle fragile items?

Yes, many sortation systems, such as tilt tray and cross-belt sorters, are designed to handle delicate or fragile items. These systems gently route products to their destination without damaging them, making them suitable for handling electronics, glassware, or other sensitive goods.

7. How fast can a sortation conveyor system sort products?

The speed of a sortation system varies based on the type of system and the product being sorted. For example, sliding shoe sorters can sort products at speeds of 150 to 450 feet per minute, making them ideal for high-volume operations. Cross-belt sorters and tilt tray sorters offer slightly slower speeds but excel in accuracy and versatility.

8. How much space is needed for a sortation conveyor system?

Space requirements vary depending on the type of sortation system you choose. For example, tilt tray sorters typically require more space due to their continuous loop design, while pop-up wheel sorters are more compact and suited for facilities with limited room.

9. What is the cost of installing a sortation conveyor system?

The cost of installing a sortation conveyor system can vary widely based on the system’s complexity, size, and specific requirements. High-capacity systems like sliding shoe or cross-belt sorters tend to have higher initial costs due to their advanced technology and capacity. However, the long-term benefits, including labor savings, improved efficiency, and scalability, often outweigh the initial investment.

10. Can a sortation conveyor system be customized?

Yes, sortation conveyor systems can be tailored to meet the specific needs of your facility. Customization options include the type of sortation system, the number of sorting lanes, product handling capabilities, and integration with other warehouse management systems (WMS) or warehouse control systems (WCS).

11. What kind of maintenance do sortation conveyor systems require?

Like any mechanical system, sortation conveyors require regular maintenance to ensure optimal performance. Preventive maintenance schedules typically include cleaning, lubricating, inspecting mechanical components, and updating control systems. Regular maintenance helps prevent breakdowns and extends the lifespan of the system.

12. How do sortation conveyors integrate with warehouse management systems (WMS)?

Sortation conveyor systems can be integrated with warehouse management systems (WMS) or warehouse control systems (WCS) to automate the sorting process fully. The WMS identifies the product and directs it to the correct destination via the sortation conveyor. This real-time data exchange improves accuracy and operational efficiency.

13. Can sortation systems handle different-sized products?

Yes, many sortation systems are designed to handle a wide range of product sizes, shapes, and weights. Systems like sliding shoe, cross-belt, and tilt tray sorters are particularly versatile and can manage everything from small parcels to larger packages.

Sortation conveyor systems are essential for optimizing the flow of products in modern warehouses and distribution centers. By answering the most common questions, we hope this FAQ section has provided clarity on the benefits, types, and factors to consider when choosing the right sortation system for your operation. If you still have questions or are ready to take the next step, our team at Lafayette Engineering is here to help you implement the best solution tailored to your needs. Reach out today for expert guidance!

Follow us on Linkedin!