The term “turn-key” is tossed around quite often and has become a buzzword in our industry. But what does it really mean? And do most companies actually deliver turn-key services?

Though we can’t speak for other companies, here’s what the term “turn-key” means for Lafayette Engineering: we can handle any project internally from start to finish — from concept to implementation.

Essentially, turn-key services means we are a one stop shop.

It is the complete design, build, and installation of material handling equipment.

So what does our turn-key service process look like for clients? Let’s take a look.

Concepting

The first step in a material handling project is the ideation or concepting phase. Every material handling project is unique because each client’s needs and facility specifications are unique.

Right after initial contact, we begin to draft plans and work closely with the client’s team to design a system concept that is built specifically to suit their facility. At this point in the journey, we provide comprehensive design consulting for our customers and truly become an extension of their project planning team.

Concepting is not only applicable to new systems projects. In fact, any system can be customized, upgraded, or retrofitted for optimum performance — with a keen eye for integration, of course.

The whole point of concepting is to generate new ideas — to redefine the possibilities of facility production output.

Once an idea is born, it is ready to be made.

Mechanical Concepting and Design

The next phase in our turn-key service is mechanical concepting and design — where ideas are brought to life. Concept drawings must be done quickly to speed the iteration process, so when we reach this phase, our engineers refine the concept drawing by designing it to meet your facilities specifications.

From storage/picking, waves, packing, order matching, and sortation, our engineers work with the client’s team to ensure the best possible design to fit the needs of the facility.

Seamless Collaboration

Bridging the gap between mechanical concepting and design and control engineering is where true turn-key services are a massive advantage. With both engineering teams available working together in-house, communication is smoother, fewer mistakes are made, and ultimately, the next phase is scheduled faster.

The Control Engineering phase is one in which many material handling service providers rely on subcontracting to accomplish — and thus, this phase is where many projects stall. But seamless collaboration between our mechanical and control engineering teams is a huge advantage for our clients.

Control Engineering

Undoubtedly, the most important aspect of any conveyor system is the control system.

Control Engineering is a hallmark of Lafayette Engineering. Once the mechanical concepting and design phase is completed, our Warehouse Control System (WCS) software application, Conveyor Works, seamlessly takes over.

Essentially, Conveyor Works acts in place of a controls team for Lafayette Engineering.

Conveyor Works uniquely combines extensive electrical engineering capabilities with the latest in technology and control devices to improve equipment utilization, increase system efficiency, reduce operational costs, and provide flexibility with your material handling systems.

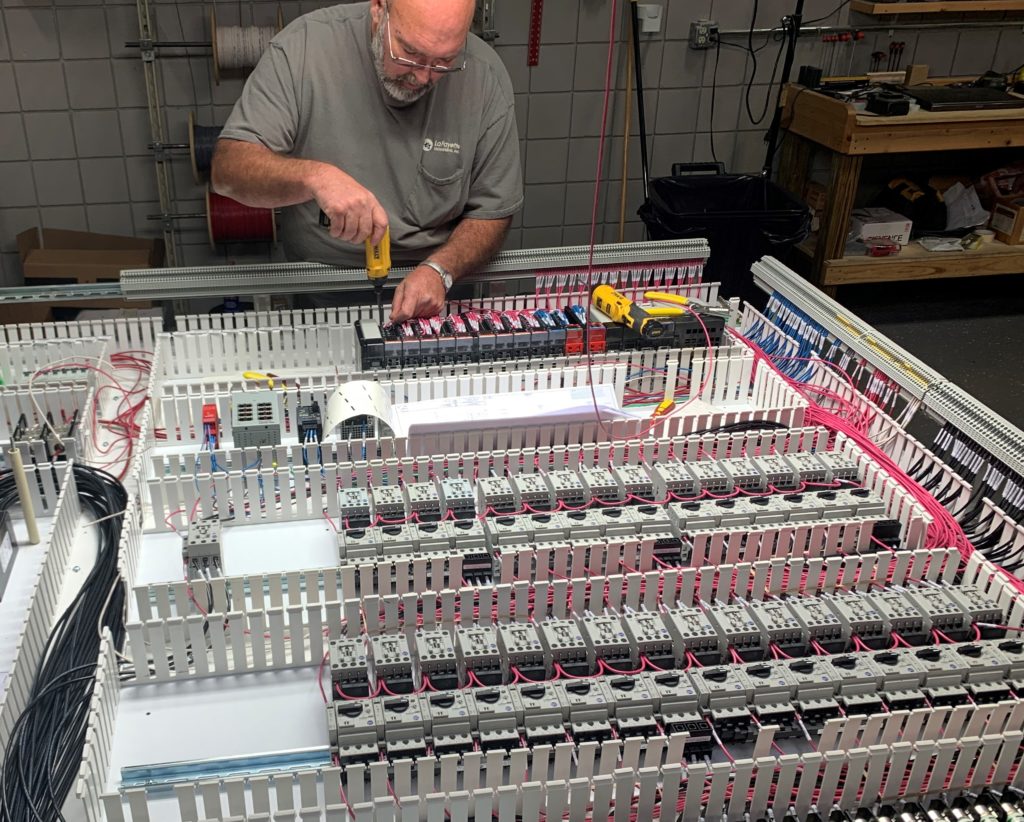

What truly sets Lafayette Engineering apart in regards to turn-key material handling services, however, is that we have a fully UL listed panel design and fabrication center located within our main office.

This allows us to have ownership over the quality of every panel required for any given project — and we don’t have to rely on an outside source. From small push button enclosures to large motor control panels, each panel is rigorously tested by our in-house electrical engineering team prior to shipping, to ensure craftsmanship and operational perfection. An in house fabrication center also affords us the flexibility to work directly with customers on timelines and adjustments to specifications.

Installation

When it comes to installation, repair, and maintenance of conveyors, a turn-key material handling project should provide engineering, mechanical, electrical, and construction services.

The installation process can be tedious, so it’s best to work with a team that has ample experience in installing, moving, and liquidating rack, tear-outs, and conveyors and has plenty of experience with many types of equipment.

When it comes to wiring the conveyor systems within a warehouse or other facilities, Lafayette represents the superior choice in field-wiring material handling systems. We provide our customers with well-trained, experienced electricians, capable of performing the most complicated projects under tight time constraints. Having oversight from one place, ensures we are able to communicate effectively and timely during all stages of a job.

PLC Installation & Testing

When the system is wired and ready for PLC installation and testing, our engineers arrive on site — the same team that worked together on the initial design of the project. They will first test to ensure that we are receiving inputs and that the outputs function correctly. They arrive with a base code ready to be deployed into the PLC, but every job has to be refined and tested to ensure that each product is moving as it should through the system.

WCS Implementation

During testing, the WCS team works closely to make sure each of your systems has the correct information prior to implementation into the system. After it is finalized and implemented our team will work closely with the controls engineer and the facility’s WCS to ensure that each team is sending and receiving the correct message and to ensure that every product delivers to the correct location.

Go Live & Beyond

It’s time.

After months of work to get a project to this stage, it is finally here. Our team will be on site to ensure that everything works as intended. Even though we have tested it as hard as we can, we can never simulate true working volume and real life situations.

This is the final mile. A strong material handling partner is with you every step of the way until the final mile is completed. To ensure the system hand off is seamless, our team will be there to train and properly hand off the system to yours. Even after our team does leave your facility, we are still with you every step of the way with our “1 year 24 hour remote support.”

We never suggest replacing your staff entirely with robots, because humans play an integral role in a production facility. Robots cannot lead, develop innovative ideas, or solve problems. We will always need the human element in warehouse operations — with robots assisting our endeavors.

Want to learn more about robotics? Give us a call at (844) 845-7580 and see how we’re working to help customers like you save time, money, and growth.