Table of Contents

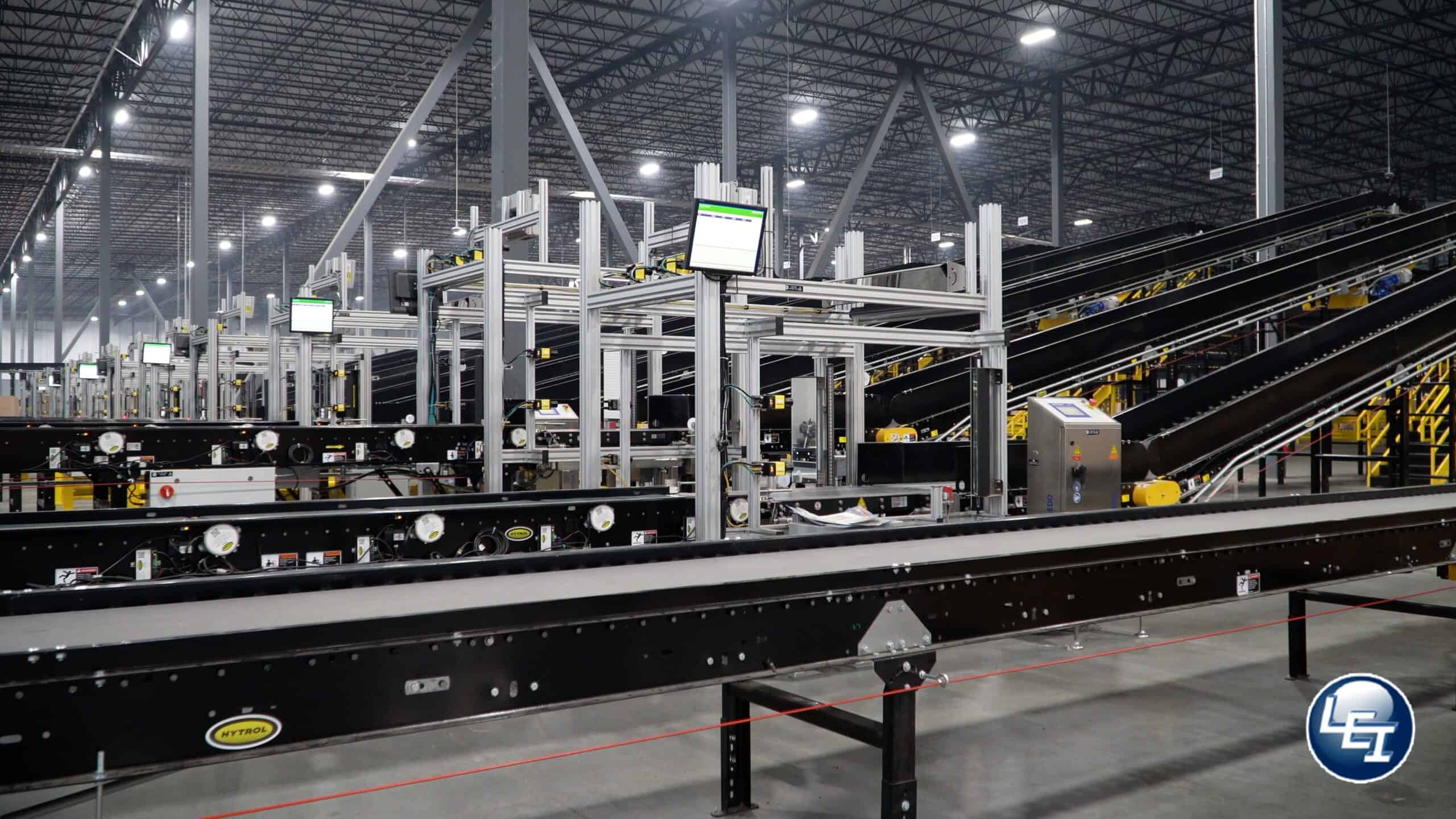

In the dynamic world of material handling and warehouse management, efficient storage solutions are paramount. Racking systems stand at the forefront of these solutions, offering structured and accessible storage that maximizes space utilization and enhances operational workflows. At LaFayette Engineering, Inc. (LEI), we specialize in designing and implementing tailored racking systems that meet the unique needs of our clients.

Understanding Racking Systems

Racking is a steel structure composed of two or more upright frames, beams, and connectors used to support materials in storage. These structures are engineered to enable customers to store the maximum amount of product in their facility while allowing accessibility for protection, organization, picking, and other organizational flow.

The primary components of a racking system include:

- Upright Frames: Vertical structures that support the weight of the stored materials.

- Beams: Horizontal supports that connect the upright frames and hold the stored items.

- Connectors: Elements that join beams and frames, ensuring structural integrity.

These components work in unison to create a system that optimizes storage capacity and facilitates efficient material handling.

Types of Racking Systems

Selecting the appropriate racking system is crucial for optimizing storage efficiency and ensuring smooth warehouse operations. Various racking systems are designed to meet specific storage needs:

Selective Pallet Racking

This is the most common type of racking system, offering direct access to each pallet. It’s highly flexible and can be easily adjusted to accommodate different pallet sizes. Selective pallet racking is ideal for warehouses that require quick access to a wide variety of products.

Drive-In and Drive-Through Racking

These systems allow forklifts to drive directly into the racking structure to pick up or drop off pallets.

- Drive-In Racking: Utilizes a single entry and exit point, following a Last-In-First-Out (LIFO) storage method.

- Drive-Through Racking: Provides access from both ends, supporting a First-In-First-Out (FIFO) approach.

These systems are suitable for storing large quantities of homogeneous products.

Push-Back Racking

In push-back racking systems, pallets are placed on a series of nested carts that move along inclined rails. When a new pallet is loaded, it pushes the previous one back. Upon retrieval, the front pallet is removed, and the ones behind roll forward. This LIFO system maximizes storage density while maintaining selectivity.

Pallet Flow Racking

Also known as gravity flow racking, this system uses inclined roller tracks to allow pallets to move from the loading end to the picking end. It operates on a FIFO basis, making it ideal for perishable goods or items with expiration dates.

Cantilever Racking

Designed for storing long, bulky items such as lumber, pipes, or furniture, cantilever racking consists of a series of arms extending from a central column, providing unobstructed access and adjustable storage heights.

Benefits of Implementing Racking Systems

Integrating a well-designed racking system into your warehouse offers numerous advantages:

- Maximized Storage Capacity: Efficient use of vertical and horizontal space increases the amount of inventory that can be stored within the same footprint.

- Improved Accessibility: Organized storage ensures that products are easy to locate and retrieve, reducing picking times.

- Enhanced Safety: Properly designed racking systems reduce the risk of accidents by securely holding products and preventing falls.

- Scalability: Racking systems can be adjusted or expanded to accommodate changing inventory levels or product lines.

- Cost Efficiency: Optimizing storage space can reduce the need for warehouse expansion, leading to cost savings.

Considerations for Choosing a Racking System

Selecting the right racking system involves evaluating several factors to ensure it aligns with your operational needs:

- Inventory Characteristics: Assess the size, weight, and turnover rate of your products.

- Available Space: Consider the dimensions of your warehouse, including ceiling height and floor space.

- Accessibility Requirements: Determine how frequently items need to be accessed and the retrieval speed required.

- Safety Regulations: Ensure compliance with local safety standards and guidelines.

- Budget Constraints: Balance the initial investment with long-term operational benefits.

Consulting with experienced professionals can help in designing a racking system that meets these considerations effectively.

LEI’s Expertise in Racking Solutions

At LaFayette Engineering, we offer comprehensive racking solutions tailored to your specific needs. Our services include:

- Pallet Racking: Standard systems for efficient pallet storage.

- Pick Modules: Customized structures that integrate various storage solutions to facilitate order picking.

- Shelving: Versatile shelving options for smaller items or carton storage.

Our advanced engineering and installation teams ensure that each project, regardless of size, is completed efficiently and to the highest standards.

Conclusion

it’s essential to assess your facility’s specific needs and select a solution that maximizes efficiency and organization. Whether you require selective pallet racking for quick access, push-back racking for high-density storage, or specialized systems like cantilever racking for oversized materials, choosing the right system can significantly impact productivity and cost savings.

At LaFayette Engineering, we specialize in designing and implementing custom racking solutions that enhance workflow, maximize space, and improve overall warehouse efficiency. Our team of experts works closely with clients to develop tailored racking strategies that align with operational goals, ensuring that every storage challenge is met with a high-quality, scalable, and cost-effective solution.

If you’re looking to upgrade your warehouse storage system, improve inventory management, or enhance operational efficiency, LaFayette Engineering is here to help. Contact us today to discuss your racking needs and discover how our solutions can transform your warehouse into a high-performance storage facility.

Visit LaFayette Engineering’s Racking Solutions to learn more!