Table of Contents

Control panel design & fabrication are fundamental components in the realm of industrial automation, serving as the central hub for managing and monitoring machinery and processes across various sectors. A meticulously designed and expertly fabricated control panel ensures operational efficiency, safety, and reliability, making it indispensable for modern industrial operations.

Understanding Control Panel Design & Fabrication

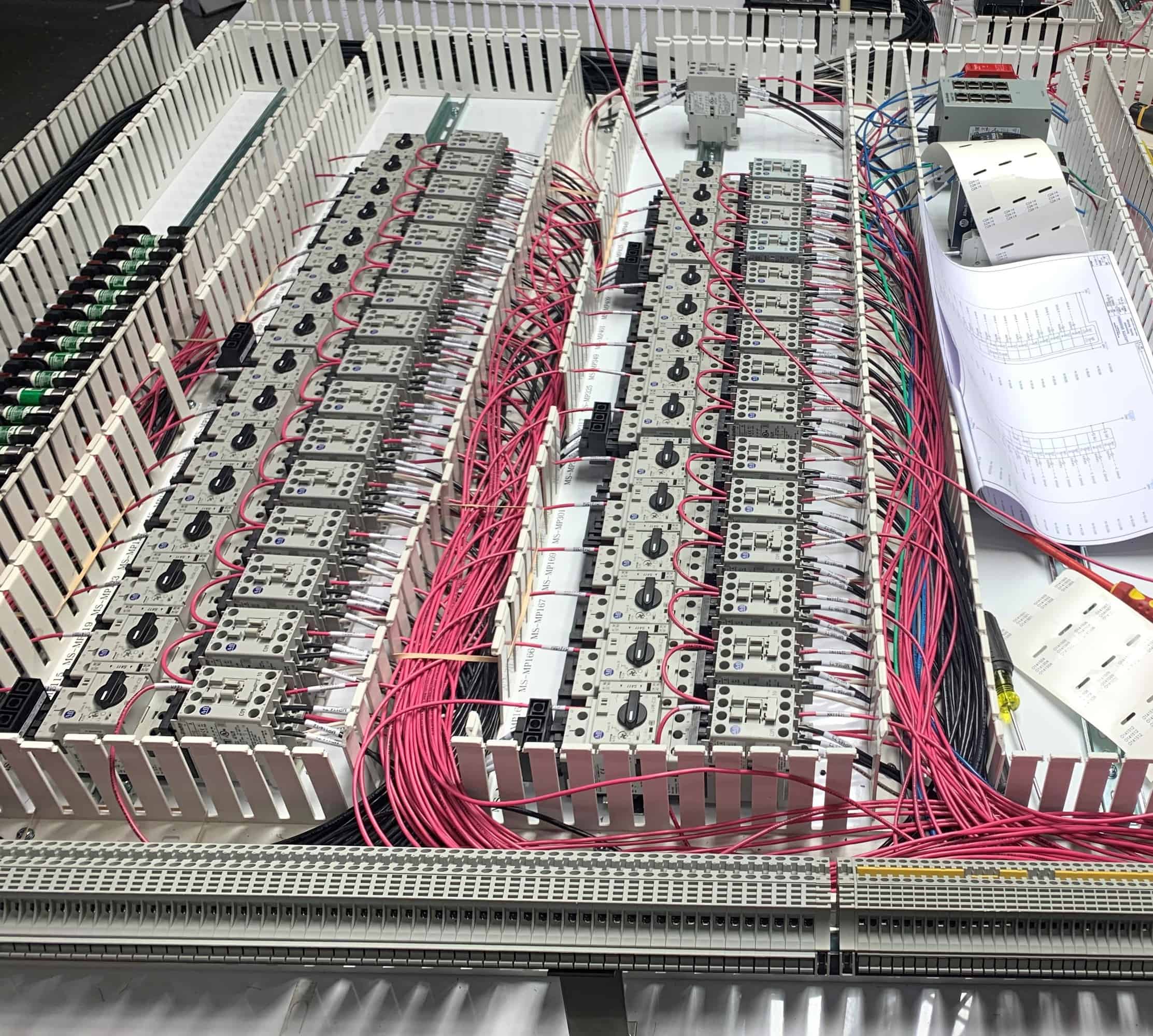

A control panel is an assembly of electrical components that directs and regulates the functioning of machinery or systems. It typically includes devices such as circuit breakers, relays, switches, and programmable logic controllers (PLCs), all organized within an enclosure. The primary function of a control panel is to provide operators with the ability to control and monitor equipment, ensuring processes run smoothly and safely.

Types of Control Panels

Control panels come in various configurations, each tailored to specific applications:

- Programmable Logic Controller (PLC) Panels: Utilized for automating machinery, PLC panels offer flexibility and ease in modifying control logic, making them suitable for complex process control.

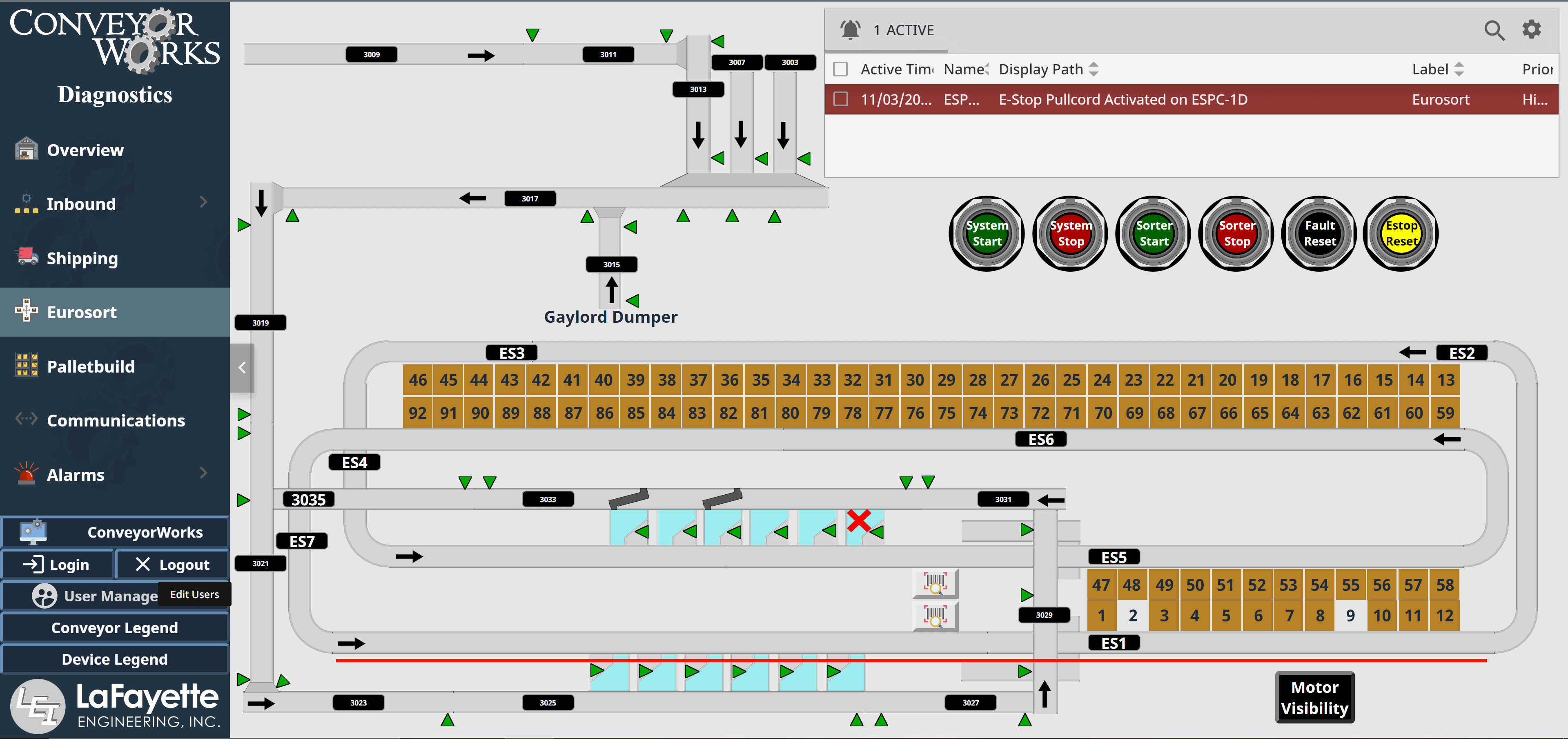

- Human-Machine Interface (HMI) Panels: These panels enable operators to interact with machinery through graphical interfaces, enhancing user experience and operational control.

- Motor Control Centers (MCCs): MCCs provide centralized control for multiple motors, facilitating efficient management and maintenance.

- Power Distribution Panels (PDPs): Essential for distributing electrical power to various components of a system, ensuring balanced and safe power management.

The Design Process

Designing a control panel involves several critical steps:

- Requirement Analysis: Understanding the specific needs of the operation, including environmental conditions, machinery specifications, and compliance with industry standards.

- Component Selection: Choosing appropriate components based on factors like durability, compatibility, and adherence to safety regulations.

- Layout Design: Organizing components within the enclosure to optimize space, ensure safety, and facilitate ease of maintenance.

- Wiring and Schematics: Developing detailed wiring diagrams and schematics to guide assembly and ensure accurate connections.

- Testing and Validation: Conducting rigorous testing to verify functionality, safety, and compliance with relevant standards before deployment.

Best Practices in Control Panel Design & Fabrication

Adhering to best practices in control panel design & fabrication enhances performance and longevity:

- Ergonomic Layout: Arranging components logically to facilitate easy access and maintenance, reducing downtime and improving safety.

- Proper Labeling: Clearly labeling all components and wiring to assist in troubleshooting and maintenance, ensuring efficient operation.

- Adequate Spacing: Providing sufficient space between components to prevent overheating and allow for future expansions or modifications.

- Compliance with Standards: Ensuring the design meets industry standards such as UL 508A, NFPA 79, and IEC 60204 to guarantee safety and regulatory compliance.

Fabrication Process

The fabrication of control panels involves translating the design into a physical product:

- Assembly: Installing components into the enclosure according to the design specifications, ensuring secure mounting and connections.

- Wiring: Routing and connecting wires as per the schematics, maintaining organization and adhering to electrical standards.

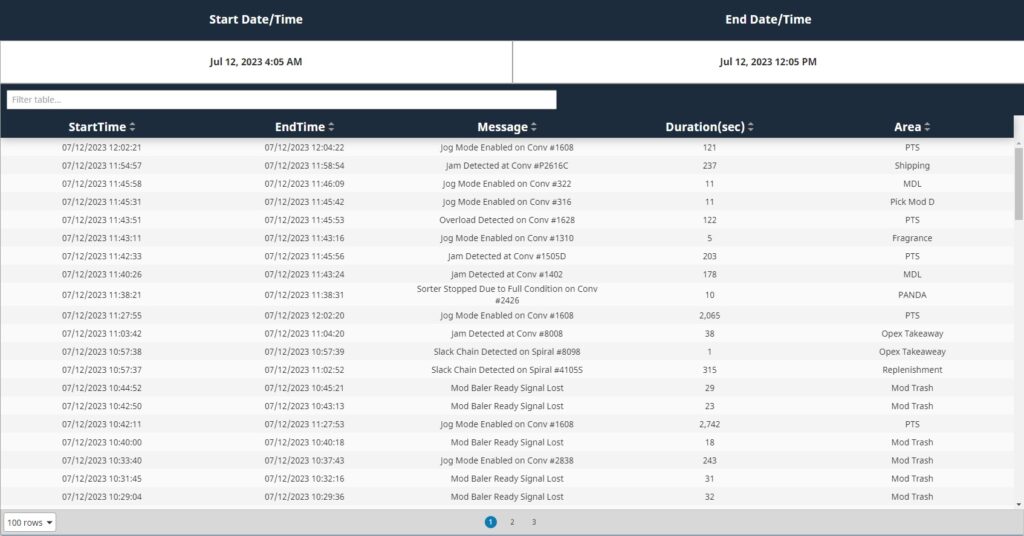

- Quality Assurance: Performing inspections and tests to verify that the assembled panel meets all design criteria and functions correctly.

- Documentation: Providing comprehensive documentation, including wiring diagrams and component specifications, to support installation and maintenance.

Why Choose LaFayette Engineering for Control Panel Design & Fabrication

LaFayette Engineering stands out as a leader in control panel design & fabrication, offering several advantages:

- In-House Expertise: With a dedicated team of engineers and technicians, LaFayette Engineering manages the entire process internally, ensuring quality control and seamless integration.

- Customization: They provide tailored solutions ranging from small push-button enclosures to large motor control panels, meeting diverse client needs.

- Quality Assurance: Each panel undergoes rigorous testing by their in-house electrical engineering team prior to shipping, ensuring craftsmanship and operational perfection.

- Efficient Turnaround: Their streamlined in-house processes allow for fast turnaround times on all panel fabrication work, ensuring timely project completion.

Conclusion

Investing in high-quality control panel design and fabrication is crucial for the efficiency, safety, and reliability of industrial operations. Partnering with experienced professionals like LaFayette Engineering ensures that your control panels are tailored to your specific needs and built to the highest standards.

Take Action

Elevate your industrial operations with expertly designed and fabricated control panels. Contact LaFayette Engineering today to discuss your project requirements and discover how their customized solutions can enhance your system’s performance. Reach out to them at https://www.lafayette-engineering.com/contact-us/.